TCF Termoventilatori Condizionatori Felsinea Srl

40057 Cadriano di Granarolo Emilia (Bologna), via Giuseppe di Vittorio 5

www.tcf.it

11

-

make sure that you have enough room for the

removal and temporary accommodation of the heat

exchanger

-

consider that an ordinary Cu/Al coil has a mass of

approximately 10 kg/m2 of frontal area per row;

therefore, prepare supports if necessary

-

completely drain the heat exchanger

-

remove the unit panel covering the hydraulic

connections and the panel through which the

exchanger will be removed

-

release the heat exchanger by undoing the relevant

clamps and extract it

-

on completion of the maintenance operations,

restore the ideal operating conditions of the

exchanger;

5.4

FAN SECTION

5.4.1

Fan

In order to keep the fan in perfect working order, WE

RECOMMEND YOU TO CHECK THE FOLLOWING AT LEAST

ONCE A MONTH:

-

The cleanliness of the shell and wheel; remove any

deposits

-

Damage and corrosion to the fan components; in

case remedy with zinc-powder paint

-

The tightness of the parts comprising the fan section

-

Seal of the vibration-damping joint fitted to the fan

supply mouth

-

Cleaning and lubrication of any DAPO control air

locks. Lubrication of this part must be performed

every six months

-

Absence of abnormal noises due to deterioration of

the bearings. If necessary, replace them. The fans

mounted on the TCF units are fitted wither with

oilless bearings (design life 2000 hours) or pedestal

bearings, depending on the operating conditions.

The pedestal bearings require periodic lubrication.

THE LUBRICATION INTERVALS show in table 3 are

subject to the environmental conditions and the

maximum temperature range during operation.

TABLE 3.

Lubrication of fan support bearings

5.4.2

Motor

In order to maintain the motor in perfect working order, TCF

recommends the FOLLOWING MONTHLY CHECKS:

-

Cleanliness: remove any deposits

-

Absence of abnormal noise due to deterioration of

the bearings

Powerful motors fitted with grease nipples require

periodic lubrication. The greasing intervals, under

normal operating conditions, are shown in Table 4.

TABLE 4

Greasing of motor bearings

5.4.3

Transmission (only T series)

In order to ensure optimum drive efficiency and to avoid

damaging the fan motor unit, the transmission must be kept

in perfect working conditions.

The following must be CHECKED EVERY MONTH:

-

The operating condition and dirtiness of the

transmission; remove any deposits

-

Damage to the drive (cracks on belt and pulleys,

frayed belt edges, worn belts and pulleys). If

necessary, replace the damaged part(s)

-

The perfect alignment of the transmission

-

The tension of the belt (see section 5.4.3.1)

5.4.3.1

Determining belt tension

To alter the tension of the driving belts you must remove the

motor.

To facilitate this operation the motors are positioned on:

-

guides

-

belt-tensioning slides

in both cases it is easy to tighten or slacken the driving belt

by means of the lock nuts and adjusting screws.

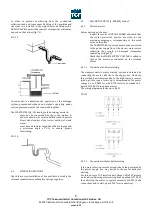

In order to determine DRIVING BELT TENSION, you must:

-

establish a centre distance (I) and block the drive

-

using a spring-operated torque wrench, apply a

force (P) on the midway point of the belt

(perpendicular to it) to obtain a deflection equal to

1/64 of the centre distance (approx. 16mm/m)

-

check that the applied force is within the values

indicated in table 5, if not, set a new centre distance

and repeat the test

TABLE 5

FIG. 26