TCF Termoventilatori Condizionatori Felsinea Srl

40057 Cadriano di Granarolo Emilia (Bologna), via Giuseppe di Vittorio 5

www.tcf.it

9

4.6.1.2.1

Selection of the airflow

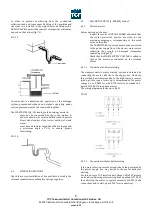

By operating on the control board (fig. 24) it is possible to

select one of the 31 available speeds:

Position the dip-switches from 1 to 5 in the adequate

position in order to obtain the desired air flow. The available

combinations for each fan are indicated in the attachment 1

(page 16).

FIG. 24

In order to avoid all problems related to current peaks during

the start-up, caused by the condensers charge of the motors

power circuit, we have arranged for a softstop/softstart

(waiting time – consumption = 0,05W) as indicated in the

connection diagram of the control box (fig. 25).

In case this

option is not used, it will be necessary to bridge the

contact between the terminals 3-6.

FIG.25

Closed=softstart

Open=softstop

4.6.1.2.2

Alarm on the pressure

This alarm uses the dip-switches from 6 to 8, and allows to

configure an alarm which will inform the user of a variation

in pressure of +25, +50, +75, +100, +150, +200, +250 or +300

Pa in relation to the reference pressure. When these alarms

activate, a LED light will switch on, and the transistor

connected between the connectors G and 2 of the control box

is a conductor.

a) how to memorize the reference pressure Pa

ref

:

Pa

ref

corresponds to the ‘starting’ pressure of the fan, that is

the one corresponding to the initial operating point of the

system (i.e. with clean filters). To elaborate the ‘built-in’

alarm you nee to memorize this pressure with the

microprocessor. Memorizing procedure: see attachment 2

page 18.

*********************************************************

**

ATTENTION

**

** The alarm in pressure is fixed only for ONE selected **

** air volume. Changing this air volume modifies the

**

** pre-set alarm – Pa

ref

is no longer correct and has to **

** be re-initialized.

**

*********************************************************

b) how to fix the increase factor

The choice of the increase factor depends on the application.

You may choose one increase out of 8 with the help of the

dip-switches from 6 to 8.

4.7

Fan

Before start-up, carry out the following checks:

-

make sure that the fan wheel is functioning

correctly by rotating it manually

4.8

NOISE LEVEL

The computation and control of noise emissions has today

become particularly important, both during the design and

installation phases.

The sound pressure values of our machines are indicated in

our technical catalogues or may be supplied directly by our

Technical Department according to the requested aeraulic

characteristics.

Being therefore aware of the sound emissions produced by

the unit, the designer must make sure that, in treated

environments, maximum values established by current

regulations are not exceeded.

It must however be stressed that every environment has its

own acoustic characteristics, which can considerably affect

the sound pressure values of mechanical ventilation systems.

THE NOISE LEVEL DATA SUPPLIED BY US SHOULD

CONSEQUENTLY BE CONSIDERED AS A CALCULATION BASE

FOR DEEPER CONSIDERATIONS, WHICH WILL TAKE INTO

ACCOUNT THE SYSTEM AND BUILDING STRUCTURE AS A

WHOLE.