TCF Termoventilatori Condizionatori Felsinea Srl

40057 Cadriano di Granarolo Emilia (Bologna), via Giuseppe di Vittorio 5

www.tcf.it

12

If the tension is not correct, the following will occur:

-

if the belt is slack, it will wear out rapidly and the

drive system will be inefficient

-

if the belt is too tight, the motor and fan bearings

will be damaged

whenever the belts are tightened, you must check that the

drive belts are aligned using an ordinary RULER (fig. 27)

FIG.27

If the pulleys are of different thickness, you must check their

equivalence as shown in fig. 28 to ensure correct installation.

5.4.3.2

Replacement of driving belt

To REPLACE THE DRIVING “V” BELT:

-

loosen the drive and remove the worn-out belt

-

check the condition and wear of the pulleys and

replace them if necessary

-

introduce the new belt without forcing; any forcing

could impair the transmission and shorten its

service life

-

align the drive and tension the belt

-

check the belt tension after about 10 working hours

5.4.3.3

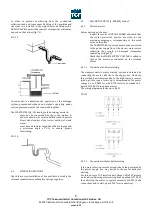

Drive with multiple-race pulleys

-

in case of drives with several belts, the belts must be

replaced at the same time. This means that there

must not be belts presenting different states of wear

in the same transmission system

-

the number of belts must always match the number

of races

-

in this type of drive system, the belt slack must be

on the same side, as shown in fig. 29, before they are

tightened

FIG. 29

5.5

TROUBLESHOOTING

The most common MALFUNCTIONS in air-conditioning units

are:

-

reduced flow rate

-

increased flow rate (excluding TA units)

-

reduction in heat exchanger efficiency

-

abnormal noise

5.5.1

Reduction in flow rate

This is the result of an uncontrolled increase in resistance in

the air moving circuit which alters the fan operating point.

The most frequent causes are:

-

excessively clogged filters

-

formation of frost or ice on the front surface of the

prefilters in particularly damp and cold climates on

units operating entirely with external air

-

blockage of the intake grille(s) (especially external

air intake)

-

fully or partially closed control air locks

-

activation of fire dampers

-

deposits on cell blocks and heat exchangers

-

inefficient fan motor unit drive

5.5.2

Increased flow rate

If the sum of the resistances in the aeraulic circuits is less

than the value considered at the design stage, the most

common causes are:

-

incorrect setting of any mechanical flow controls or

zone air locks

-

non-replacement

of

filters

after

ordinary

maintenance operations

-

open or partially closed inspection doors

5.5.3

Reduced heat exchanger efficiency

The most common causes are:

-

clogging of finned pack

-

formation of air bubbles inside the exchangers