TCF Termoventilatori Condizionatori Felsinea Srl

40057 Cadriano di Granarolo Emilia (Bologna), via Giuseppe di Vittorio 5

www.tcf.it

1

GENERAL INDEX

0. INTRODUCTION

2

1.

DESCRIPTION OF THE AIR

2

CONDITIONING UNIT

1.1

COMPOSITION

2

1.2

PERMITTED USE

2

2.

CONTROL,PACKING,TRANSPORTATION

2.1

FACTORY INSPECTION OF THE SUPPLY 2

2.2

PACKING

2

2.3

LOADING,TRANSPORT,UNLOADING

2

3.

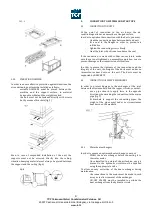

ASSEMBLY ON SITE

3

3.1

POST-TRANSPORTATION CHECK

3

3.2

PRESERVATION ON SITE

3

3.3

POSITIONING

3

3.3.1

Dimensions of installation room

3

3.3.2

Base frame

3

3.3.3

Vibration damping

3

4.

CONNECTION TO SYSTEMS AND START-UP

4.1

CONNECTION TO DUCTS

4

4.2

CONNECTION OF HEAT EXCHANGERS

4

4.2.1

Water heat exchangers

4

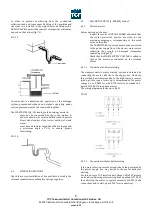

4.3

DRAINAGE AND SIPHONING

5

4.4

FILTRATING SECTIONS

6

4.5

FAN-MOTOR UNITS (3-PHASES) series T 6

4.5.1

Electric motors

6

4.5.1.1 Connection for direct starting

6

4.5.1.2 Connection for star-delta starting

6

4.5.1.3 Dual speed three-phase motor

7

4.5.1.4 Permitted start-up time

7

4.5.1.5 Recommeded connection and protection 7

accessories

4.5.2

Fan

7

4.5.3.

Transmission

8

4.6

FAN-MOTOR UNITS (1-PHASES) series

TA, PA, TA

8

4.6.1

Electric motors

8

4.6.1.1 3-speed fans series TS and PA

8

4.6.1.2 Self-regulating fans series TA

8

4.6.1.2.1 Selection of the airflow

9

4.6.1.2.2 Alarm on the pressure

9

4.7

Fan

9

4.8

NOISE LEVEL

9

5.

MAINTENANCE

10

5.1

FOREWORD

10

5.2

FILTRATING SECTIONS

10

5.2.1

Reconditionable synthetic filters 10

5.2.2

Non-reconditionable bag filters 10

5.2.2.1 Replacement load loss chart

10

5.3.

HEAT EXCHANGERS

10

5.3.1

Water heat exchangers

10

5.3.2

Extraction of water heat exchangers 10

5.4

FAN SECTION

11

5.4.1

Fan

11

5.4.2

Motor

11

5.4.3

Transmission (only T series)

11

5.4.3.1 Determining belt tension

11

5.4.3.2 Replacement of driving belt

12

5.4.3.3 Drive with multiple-race pulleys 12

5.5

TROUBLESHOOTING

12

5.5.1

Reduction in flow rate

12

5.5.2

Increase in flow rate

12

5.5.3

Reduced heat exchanger efficiency 12

5.5.4

Abnormal noise level

13

6.

SAFETY

13

6.1

SAFETY-RELATED FEATURES OF 13

AIR-CONDITIONING UNITS

6.2

SAFETY NOTICES APPLIED TO THE 13

UNITS

6.3

PRACTICAL ACCIDENT-PREVENTION 13

TIPS

7.

WARRANTY

13

8.

ATTACHMENT 1

14

9.

ATTACHMENT 2

16

10.

ATTACHMENT 3

17