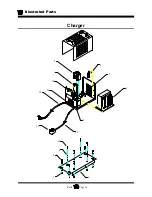

Illustrated Parts

Parts

Page 32

Miscellaneous Electrical

Item No.

Part No.

Description

Qty

1

73-005-10

Reverse alarm (optional), BULLARD MPA-II, 97DB

2

71-124-00

Switch, battery disconnect

1

3

78-010-30

Fuse panel

1

4

79-820-05

FUSE,ATO,15 AMP

5

79-820-06

FUSE,ATO,20 AMP

6

75-148-93

Harness, control

1

7

75-149-97

Harness, power

1

8

71-900-05

Flasher, turn signal

1

9

73-004-20

Horn

1

10

62-033-56

Throttle module assembly (includes #11)

1

11

85-295-00

Spring, extension for #10

1

12

71-303-01

Relay, reverse light

1

13

73-012-80

DC-DC converter

1

14

74-050-00

Wiper motor

1

15

74-051-10

Wiper arm

1

16

74-052-10

Wiper blade

1

17

72-022-00

Tail light

2

18

72-022-51

Mounting ring for tail and reverse lights

3

19

72-035-00

Reverse light

20

72-076-00

Head light

2

21

72-050-10

Front turn signal

2

22

92-206-50

Mirror, rearview, inside cab

1

23

91-017-11

Mirror, left side

1

24

91-017-12

Mirror, right side

1

25

91-017-14

Bracket, mirror mount

2

26

72-023-20

Strobe light (optional)

Summary of Contents for ET-015-00

Page 2: ......

Page 14: ...TAYLOR DUNN...

Page 28: ...TAYLOR DUNN...

Page 48: ...Maintenance Service and Repair Steering Page 12 Exploded View of Steering Gear...

Page 60: ...Maintenance Service and Repair F2 F3 Transmission Page 12 EXPLODED VIEW...

Page 71: ...Maintenance Service and Repair Brakes Page 11 Rear Brake left side shown...

Page 72: ...TAYLOR DUNN...

Page 80: ...TAYLOR DUNN...

Page 90: ...TAYLOR DUNN...

Page 94: ...TAYLOR DUNN...

Page 100: ...TAYLOR DUNN...

Page 114: ...TAYLOR DUNN...

Page 116: ...TAYLOR DUNN...

Page 130: ...Illustrated Parts Parts Page 14 Rear Axle Axle tube 4 5 6 7 3 2 Rear Brakes...

Page 132: ...Illustrated Parts Parts Page 16 Rear Suspension 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Drive Shaft...

Page 134: ...Illustrated Parts Parts Page 18 Motor direct drive Motor Mount direct drive...

Page 142: ...Illustrated Parts Parts Page 26 Instrument Panel dash...

Page 144: ...Illustrated Parts Parts Page 28 Speed Control Panel 1 2 3 4 5 6 7 8 9 10 11 12 4...

Page 152: ...Illustrated Parts Parts Page 36 Charger 2 1 15 12 11 4 3 5 8 10 6 7 9 13 14 16...