8

■

Floor surface

○

Ensure that the material or finishing of the floor surface is waterproof or has a waterproof coating applied.

○

Always ensure that the floor surface is horizontally level so that the product slides smoothly.

○

Ensure that the floor surface is smooth and free from bumps around the attachment areas.

○

Raised pipes

【

Plumbing specifications

】

Drain

Rc 1/2”

VU40/VP40

Hot water / water supply

○

If the floor surface is tiled, cracks and so on may occur when fastening the bolts during installation of the fixing base.

If this looks likely to happen, use the floor template as a reference, and change the material of the installation area

to another material such as plywood or mortar, etc.

○

The following levels of strength are required for the floor surface.

Wooden floor

Mortar floor

Mortar thickness of 50 mm or more

Special floor (stone finish, etc.)

A foundation with levels of strength listed above around the installation areas is required.

Plywood thickness of 30 mm or more (two 15 mm sheets joined together)

○

Be sure to take the necessary precautions to prepare for and prevent possible water leakage.

○

Use waterproof flooring materials.

○

When installing the product on the 2nd floor or higher, be sure to observe waterproofing (waterproofing works,

installing a pan made of stainless panel, etc. or installing water leakage sensor.).

○

Be sure to cover an opening of raised plumbing and a connection of pipes by caulking material, etc.

■

Request measures to prevent water leakage under the floor and downstairs

【

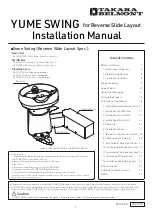

Raised pipe dimension

】

Raise dimensions

Hot water supply

Drain

Under the floor plumbing

Wall mounted plumbing

Above the floor plumbing

60mm

60mm

90mm

140mm

90mm

140mm

Water supply

Plumbing Spec.

60mm

90mm

140mm

■

Installation of pipes

■

”Precautions during installation of pipes”

The following are important points to adhere during the installation of pipes. Read through

the details carefully and ensure that the pipes are installed correctly.

○

When installing this product, ensure that installation of pipes adheres to the instructions outlined in “Precautions

during installation of pipes”. Installing pipes without observing the precautions will mean water may not

mix properly, and a set temperature may not be achieved.

○

This product is designed for indoor installation. Always install this product indoors.

○

Do not use pipes made of materials that may introduce rust for the water supply pipe. In general, VP pipes or

other materials specified by regulations in that particular region, are recommended for installation.

○

In general, Type L deoxidized copper pipes are recommended for hot water pipes.

○

In general, the same diameter and same pressure is recommended for hot water pipes and water supply pipes.

○

Always use a reamer to deburr the ends of cut pipes.

○

Avoid using inverted U-shaped pipes (siphon) as these can cause air to become trapped.

Installation Conditions

3

○

Do not use the tile or glass and so on for the floor surface where caster rail is attached.

Summary of Contents for YUME SWING

Page 35: ...35 MEMO...