37

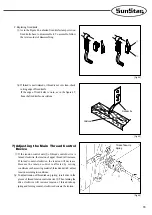

C. Y-shaft timing belt

a) Timing belt at motor operating parts

①

Check timing belt tension of the Y-motor operating

parts by detaching the Y motor base cover from the

body of the machine and using sonic belt

tensiometer.

②

Adjust timing belt tension of the Y-motor operating

parts by flipping with fingers or sticks the middle of the

belt that stretches from the operating pulley

ⓐ

to the

final operating pulley

ⓑ

. Make sure that the measured

value of the sonic belt tensiometer is 30 ~ 31kgf.

③

Input data for the sonic belt tensiometer, when adjusting the

timing belt tension of the Y-main shaft motor operating parts.

Weight: 003.8gf/m

Wide: 40mm/#R

Span: 137mm

④

In order to adjust timing belt tension of the Y-motor

operating parts, unfasten the four idler bracket fixing

screws

ⓒ

. Then pushing the idler

ⓑ

to the left will

increase the tension; while pushing it to the right

will decrease the tension.

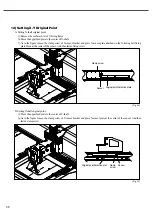

b) Y-conveying timing belt

①

Check Y-shaft timing belt tension by moving X-fixing/conveying frame, as in the Figure, to the frontal extreme and

using sonic belt tensiometer.

②

Adjust Y-shaft timing belt tension by flipping with fingers or sticks the middle of the belt that stretches from the end of

the feed bracket to the center

Ⓑ

of the operating pulley. Make sure that the measured value of the sonic belt tensiometer

is 37 ~ 38kgf.

③

Input data for the sonic belt tensiometer, when adjusting Y-shaft timing belt tension.

Weight: 3.8gf/m

Wide: 48mm/#R

Span: 840mm

④

In order to adjust Y-shaft timing belt tension, unfasten the tension base clamp screws

①

and turning tension adjusting

bolt

②

. Turning the tension adjusting bolt

②

clockwise will increase the belt tension; while turning it counter-clockwise

will decrease the tension.

⑤

After adjusting the tension, fasten tension base clamp screw

①

firmly.

[ Fig. 52 ]

ⓐ

ⓒ

ⓓ

ⓑ

[ Fig. 53 ]

②

①

Ⓑ