42

No.

1

3

Type of Breakdown

Error on operation or drive

of machine

Cause

Too loose belt tension and damage on belt

Troubleshooting

Adjust the belt tension or exchange it

Needle break

4

Thread is cut

5

Stitch skipping

Excessive tension of upper thread and

under thread

Adjust the tension

Excessive tension and stroke of take-up

lever spring

Adjust the tension and stroke of take-up lever

spring

Crack on the thread controlling hole of

shuttle surface spring

Exchange the shuttle surface spring

Use of bending needle

Exchange the needle

Use of needle whose size is not fit to thread Exchange the needle

Wrong installation of needle

Reinstall of needle

Improper timing and needle

Readjust the timing for a needle and shuttle

Large interval between a needle groove

and shuttle point

Readjust the timing for a needle and shuttle

Excessive tension and stroke of take-up

lever spring

Fuse shortage for main power or after

circuit

Deviation from Y and Y limit of feed bracket

Check the fuse shortage of main shaft drive

motor in a controller box, exchange it

Slackness of main drive belt

Wrong position of upper shaft sensor plate

or photo sensor

Adjust the belt tension

Adjust the position of upper shaft sensor plate or

exchange the photo sensor

Damage on needle(Bending of needle,

cracks on needle hole or groove, and

abrasion or transformation of needle tip)

Exchange the needle

Move the feed bracket to normal place (inside

limit switch)

Install the needle properly

Bad position of stopping

position

2

Adjust the distance properly between a needle

and shuttle

Contact of needle with shuttle

Wrong installation of needle

Wrong insertion of thread

Insert the thread properly

Wrong installation of needle (Needle height,

needle direction)

Reinstall the needle

Exchange the needle

Damage on needle ( Bending of needle,

cracks on needle hole or groove, and

abrasion or transformation of needle tip)

Adjust the tension and stroke of take-up lever

spring

77

CAUSE OF BREAK-DOWN AND TROUBLESHOOTING

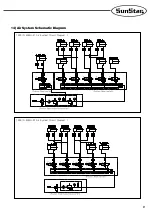

X축 모터 드라이버