35

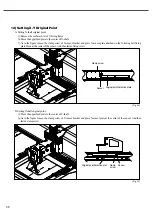

[ Fig. 50 ]

11) Adjusting tension of operating belt

A. Specification of operating belt tension adjusting device. (Sonic belt tensiometer)

ⓐ

Model: U-505 series sonic belt tensiometer standard.

ⓑ

Manufacturer: UNITTA.

B. X-shaft timing belt

a) Motor operating timing belt.

①

To check tension of X-motor operating timing belt, use sonic belt tensiometer after separating X-motor base surface

cover from the main body.

②

Adjust X-motor operating timing belt to make sure that the measured value of sonic belt tensiometer should be 12~13kg

when the belt center

Ⓐ

of the final operating pulley

⑤

and operating pulley

③

is flipped over with finger or stick.

③

When adjusting tension of X-motor operating timing belt, input data of sonic belt tensiometer is as followings.

Weight: 2.5gf/m

Wide: 25mm/#R

Span : 116mm

④

When adjusting tension of X-motor operating timing belt, loosen nut

②

linked to tension adjusting bolt

①

and turn

tension adjusting bolt

①

clockwise. Then operating pulley

③

and motor

④

will be pushed into the direction of bolt,

which leads to the increase of tension of timing belt. And turning tension adjusting bolt

①

counterclockwise will

decrease the belt tension.

⑤

After adjusting tension, make sure to fasten nut

②

.

③

② ①

⑤

Ⓐ

④

[Note]

1. Adjusting tension of operating belt might affect stitch quality and operation. Therefore when tension adjustment is

necessary, turn to the company serviceman or an expert.

2. Make sure to turn off the power switch when adjusting tension of each operating belt.