29

[Cautions]

If the presser foot operating cam is improperly positioned, The up-and-down moving of presser foot is in inconformity,

therefore the presser foot may collide with the needle bar.

4) Adjusting the Presser Foot Devices

A. Conform the end of presser foot operating cam to the center of punched mark, and conform the cam’s punched line to the

punched mark of upper axis, and then tighten Clamp

①

.

[Fig. 33]

[Fig. 34]

Presser

Bar

Presser

Foot

①

17mm

Presser Bar

Holder

→

→

①

Upper

Shaft

Engraved

Point

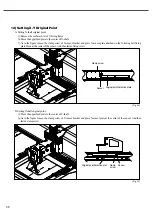

B. Project the presser bar about 17

㎜

from the presser bar

holder, check if the needle passes through the center of

presser foot, then tighten Clamp

①

.

C. Loosen Fork Crank Clamp

①

, and place the single screw

②

of presser foot link to the right of the adjusting arm.

D. Conform the fixing single screw

③

of presser foot moving link to the end

④

of position link stopper.

E. To set up 4

㎜

of the interval between Presser Bar Holder and Presser Bar Bushing, rise up the presser bar and tighten Fork

Crank Clamp

①

.

[ Caution ]

If there is space between presser bar handle and presser bar bush, interference and noise is occurring during machine

operation. Screws are not fastened tightly after adjustment; it can cause breakage during operation.