THIS PRODUCT IS MANUFACTURED AND CONTROLLED UNDER A QUALITY MANAGEMENT SYSTEM CERTIFIED TO ISO 13485 MEDICAL DEVICE STANDARDS.

FOR RESEARCH USE ONLY. NOT INTENDED FOR HUMAN OR ANIMAL DIAGNOSTIC OR THERAPEUTIC USES.

TOLL FREE PHONE

1 800 667 0322

y

PHONE

+1 604 877 0713

VERSION 2.4.0

y

y

FOR GLOBAL CONTACT DETAILS VISIT WWW.STEMCELL.COM

DOCUMENT #28940

25

6

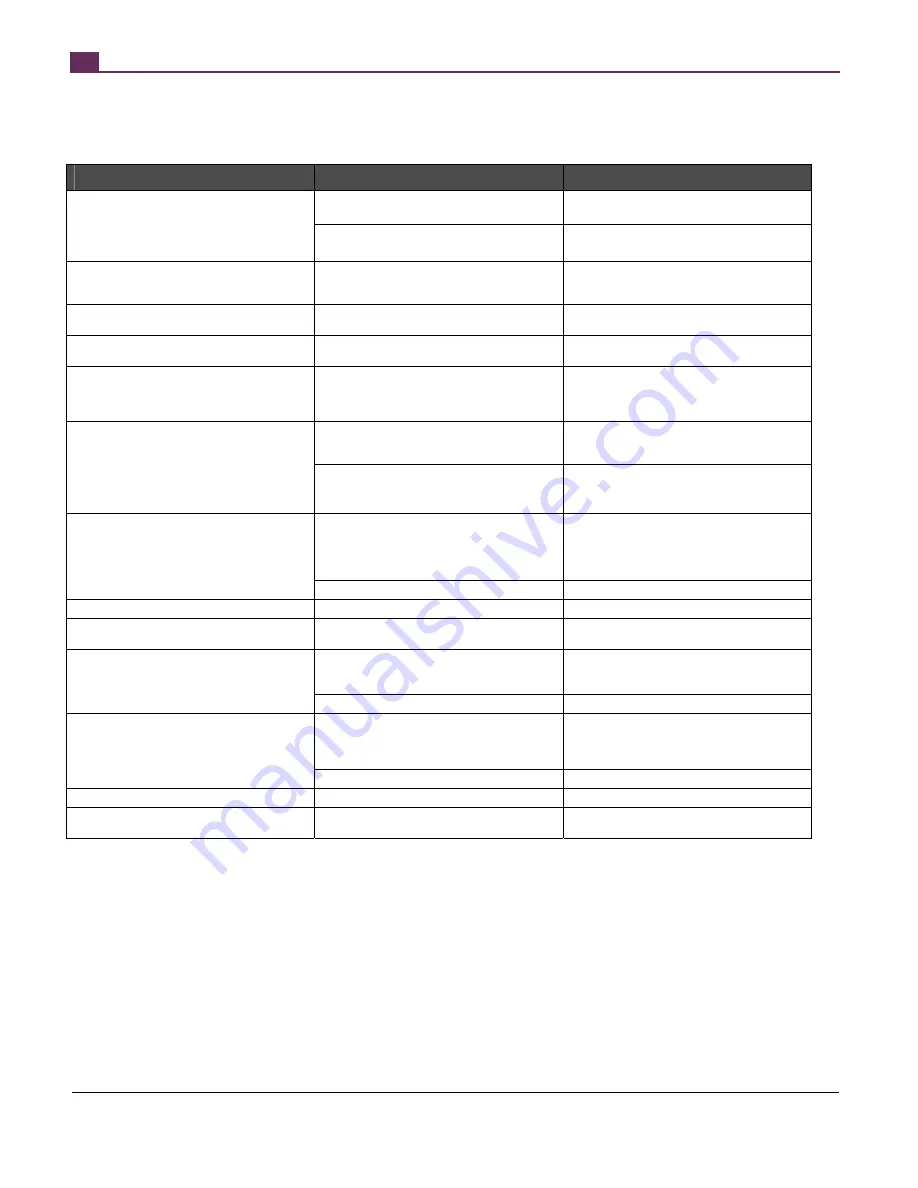

TROUBLESHOOTING

RoboSep™ presents error messages to help diagnose some types of problems that may occur during use. Please record the message

before calling Technical Support. The following tables address other potential issues that are not flagged as errors.

PROBLEM

POTENTIAL CAUSE

SOLUTION

RoboSep™ screen does not turn on. No sound,

movement, or sign of activity within 30 seconds

of attempting to power up the instrument.

Faulty fuse.

Check that the fuses are correctly installed in

described in Section 5.6.

No power to outlet.

Check that the outlet is active by connecting a

known working device such as a lamp.

Operating system boots up but RoboSep™ fails

to fully initialize.

Power switch not left on long enough. It takes up

to 10 seconds for the electronics to fully reset

after the power switch has been turned off.

After shutdown, turn off the power switch and

count to 10 before turning the power back on

again.

RoboSep™ won’t resume a paused run.

Lid up. RoboSep™ will not run if the lid is in the

raised position.

Lower the lid and press Resume on screen.

RoboSep™ won’t shut down because the basic

shutdown protocol won’t load.

Previous run not complete or needs to be

unloaded.

Let run finish. Press unload button on the

Sample Processing screen.

Reagents left in tips.

RoboSep™ leaves a residual volume in tips

when pipetting small volumes.

This is a normal operation and is required to

meet the accuracy requirements for low volume

reagent addition. The residual volume is 20 µL

or less.

Missed tip pick-up.

Tip rack not placed properly on the carousel.

Make sure that the tip rack is seated properly by

pushing down firmly on the outside of the

exposed portion.

Robotic arm or carousel was bumped during

operation.

Only operate with the lid down.

If the above measures fail to solve the issue,

contact Technical Support.

Tip head spits hydraulic fluid.

Hydraulic fluid line contamination.

Fill hydraulic fluid bottle with 70% isopropanol or

70% ethanol and prime >4 times. Leave alcohol

in line for >1 hour (longer times preferred), prime

>4 times with sterile deionized water. If problem

persists, contact Technical Support.

Damage to fluid line.

Contact Technical Support.

Tips not well aligned with tubes.

Positional calibration is required.

Contact Technical Support.

Tip rack separates at the snap joint when

removing cap.

Excess force applied at this joint by mistake.

Ensure only the top cap is removed.

Missed tip stripping action.

Tip stripping arm not moving.

Arm is out of position. Power down the

instrument, open the lid, and pull the tip stripping

arm out. Restart RoboSep™.

Tip stripping arm misaligned.

Contact Technical Support.

Priming step missed or incomplete: No water

ejected from the tip head prior to run.

Connections in hydraulic system are leaking air.

Make sure the connection between the hydraulic

fluid bottle and tubing is seated correctly by

disconnecting and reconnecting firmly.

Hydraulic fluid bottle is empty.

Refill bottle.

Can’t load protocol in Protocol Editor.

File is read-only.

Change file property.

Custom protocol does not appear in protocol

database.

File label is not unique.

Create unique label for protocol using Protocol

Editor (see Section 3.3).

Summary of Contents for RoboSep 20000

Page 1: ...RoboSep The Fully Automated Cell Separator T E C H N I C A L M A N U A L V E R S I O N 2 4 0 ...

Page 33: ......

Page 34: ......

Page 35: ......