16

SIME SUPPORT THE

BENCHMARK INITIATIVE

All relevant sections of the logbook must be

filled in at the time of installation and there-

after service information on the back page

of the logbook.

Commissioning of the boiler is not com-

plete until the logbook is filled in.

5.1

D.H.W. PRODUCTION

The preparation of hot water is guaranteed

by the glass enamelled tank unit with mag-

nesium anode for the protection of the tank

and inspection flange for its control and

cleaning. The magnesium anode must be

checked annually and substituted when it is

worn. If the boiler does not produce hot

water, make sure that the air has been

released by pressing on the manual vents

after having switched off the main switch.

5.2GAS VALVE

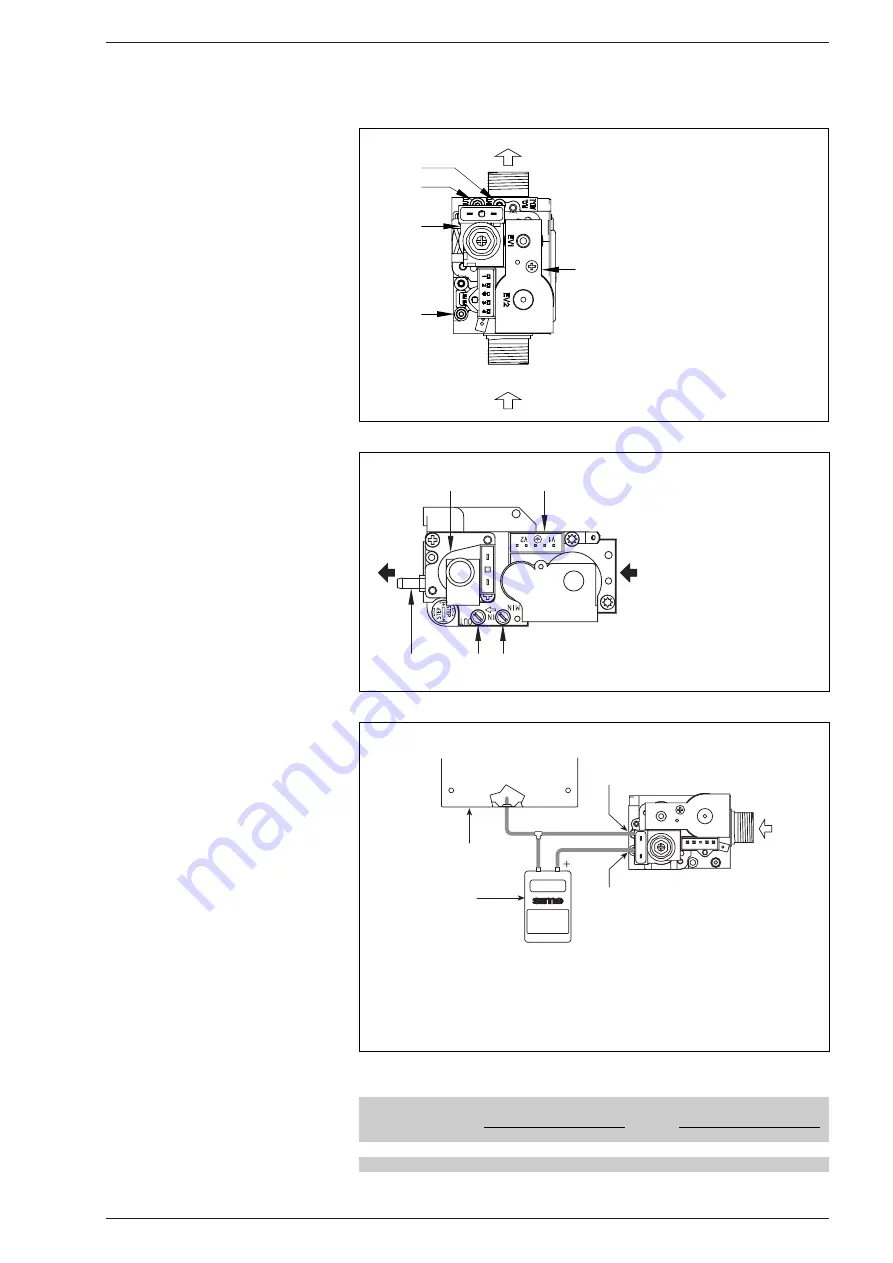

The boiler is produced with SIT 845 SIGMA

gas valve (fig. 19) and HONEYWELL VK

8105N gas valve (fig. 19/a).

NOTE: In case of replacement of the SIT

gas valve to HONEYWELL or vice-versa,

set propertly the Modureg connector of

electronic panel (14 fig. 17 - point 4.1.2).

With the jumper inserted the boiler is

setted for the SIT gas valve; with the

jumper removed the boiler is setted for

the HONEYWELL gas valve.

The gas valve is set at two pressure values:

maximum and minimum, that correspond,

according to the type of gas, to the values

indicated in

Table 6

.

The setting of the gas

pressure at minimum and maximum values

is carried out by SIME: variations are dis-

couraged. Only in the passing from one

type of gas supply (methane) to another

(butane or propane) is a change in the

working pressure allowed.

It is essential that this operation is car-

ried out by authorised personnel.

Once the change in working pressure has

been carried out, seal the regulators.

When proceeding with the setting of the

pressure, it is necessary to follow a pre-

established order: first the MAXIMUM and

then the MINIMUM.

5.2.1

Maximum and minimum

pressure adjustment

SIT 845 SIGMA

In order to carry out the setting of the max-

imum pressure proceed in the following

way (fig. 21):

– Connect the differential manometer as

shown in fig. 20.

– Remove the plastic cap of the modulator (1).

– Place the D.H.W. potentiometer knob on

the maximum value.

5

USE AND MAINTENANCE

3

4

2

1

5

6

Fig. 19

KEY

1

Modulator

2

EV1-EV2 coils

3

Pressure inlet upstream

4

Pressure inlet downstream

5

VENT plug

TABLE 6

Burner max.

Modulator

Burner min.

Modulator

Gas type

pressure

current

pressure

current

mbar

mA

mbar

mA

Methane (G20)

11.3

130

2.2

0

Butane (G30)

28.9

165

5.5

0

Propane (G31)

36.2

165

7.3

0

1

2

4 3

5

Fig. 19/a

1

2

3

4

Fig. 20

KEY

1

Modulator

2

EV1-EV2 coils

3

Pressure inlet upstream

4

Pressure inlet downstream

5

VENT plug

KEY

1

Pressure inlet downstream

2

VENT plug

3

Sealed chamber

4

Differential manometer

Summary of Contents for Planet Super 4 F.S.

Page 1: ...Planet Super 4 F S Installation Servicing Instructions GB...

Page 27: ......

Page 29: ...Planet Super 4 F S User Instructions GB...

Page 30: ......

Page 41: ...Planet Super 4 W M...

Page 74: ......

Page 75: ......