18

3 .4

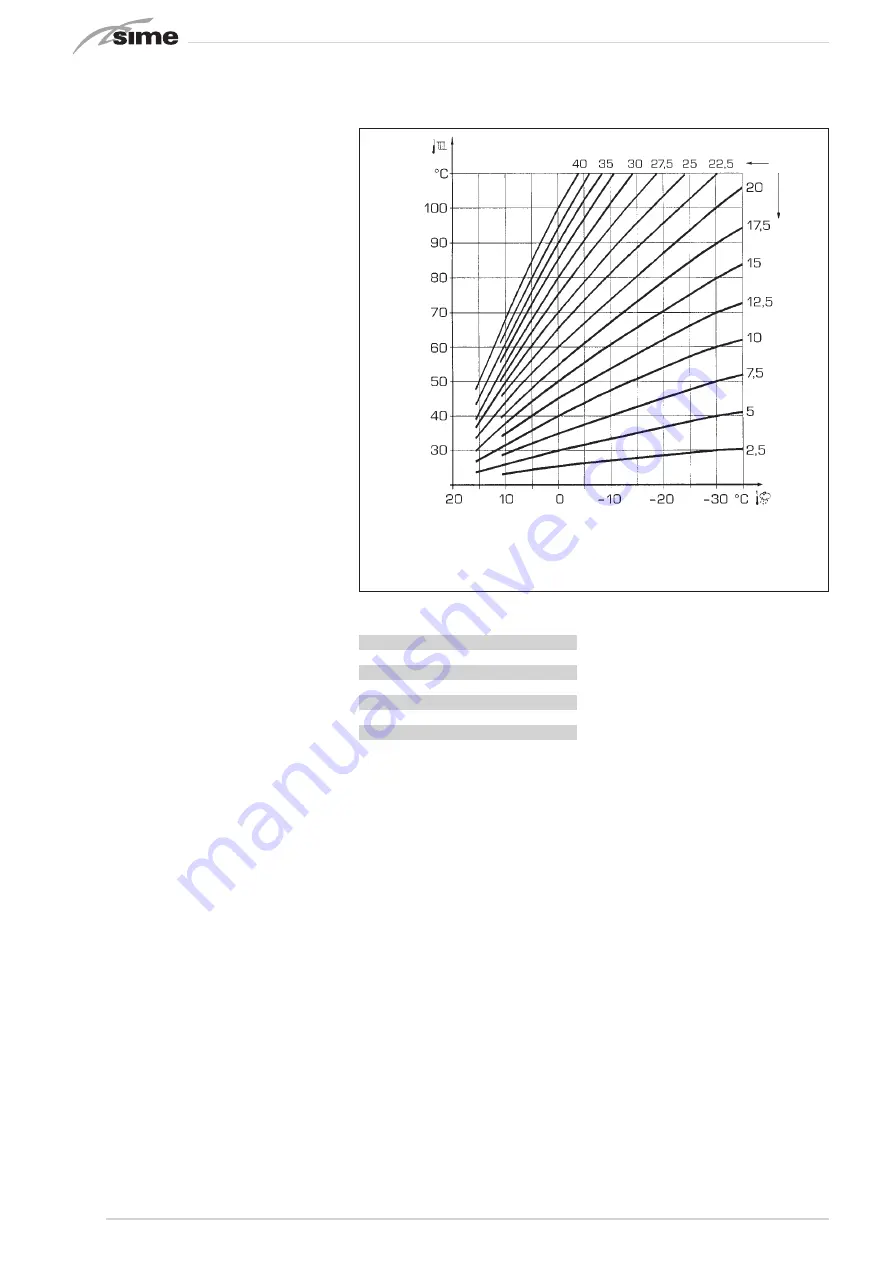

EXTERNAL SENSOR

CONNECTED (fig . 13)

If an external sensor is connected, the

heating setpoints can be derived from

the climatic curves as a function of the

external temperature, within the range

described in par. 3.3 (PAR 22 for zone 1,

PAR 25 fro zone 2 and PAR 28 for zone 3).

The climatic curve can be chosen from the

range 3 to 40 (in steps of 1). Increasing

the slope shown in fig. 13 increases the

delivery temperature as a function of the

external temperature.

3 .5

CONTROLLER FUNCTIONS

The electronic controller has the follow-

ing functions:

– Heating and DHW circuit anti-freeze

protection (ICE) .

– Flame ignition and detection.

– Control panel adjustment of the boil-

er’s power and gas.

– Anti-locking function: runs the pump

for a few seconds every 24 hours of

disuse.

– Anti-legionella function for storage

tanks.

– Chimney sweeper function enabled

from the control panel.

– Sliding temperature scale with exter-

nal sensor connected. This is set on

the control panel, and can be set sepa-

rately for heating circuit 1 and heating

circuits 2 and 3.

– Control of three independent heating

circuits.

– Automatic adjustment of the ignition

and maximum heating power. These

adjustments are made automatically

by the controller to ensure flexible

operation of the system.

– Interface for the following devices:

SIME HOME remote control, code

8092281, RVS temperature regulators,

connection to the mixed zone control

board MIX ZONE code 8092275/76, to

the SOLAR board, code 8092277/76,

and to the MODBUS board, code

8092278. To configure the devices with

the boiler's controller, you must set

installer parameter

PAR 10

.

3 .6

TEMPERATURE SENSORS

Table 4

shows the resistance values (Ω)

output by the heating, DHW and flue gas

sensors as a function of temperature.

If the heating delivery (SM), heating

return (SR) and flue gas (SF) sensors

are malfunctioning, the boiler will not

run .

3 .7

ELECTRONIC IGNITION

Flame ignition and detection are handled

by two electrodes on the burner which trip

within 1 second when the flame is acciden-

tally extinguished or the gas supply fails.

3 .7 .1 Operating cycle

The burner ignites within at most 10 sec-

onds after the gas valve is opened. Failure

to ignite, resulting in the lock-out signal

being tripped, may be due to:

–

No gas supply

The ignition electrode will spark for at

most 10 seconds, after which a fault is

reported if the burner does not ignite.

This may happen on first ignition or after

long periods of disuse due to air in the

gas line.

It may be caused by the gas valve being

closed, or one of the valve coils may be

broken so that the valve does not open.

–

The ignition electrode does not spark

The boiler detects only gas delivery to

the burner, the fault is reported after 10

seconds.

This may be due to the electrode cable

being broken or improperly hooked up.

The electrode may be grounded or worn:

replace it. The controller board is faulty.

–

No flame detected

After ignition, the electrode continues

sparking even though the burner has

ignited.

After 10 seconds the electrode stops

sparking, the burners turns off and the

fault is reported.

This may be due to the electrode cable

being broken or improperly hooked up.

The electrode may be grounded or worn:

replace it. The controller board is faulty.

A power failure will immediately extinguish

the burner: the boiler will ignite again as

soon as power is restored.

TABLE 4

Temperature (°C)

Resistance (Ω)

20

12,090

30

8,313

40

5,828

50

4,161

60

3,021

70

2,229

80

1,669

Fig. 13

WARNING: The curves are calculated for an ambient tempera-

ture of 20°C . The user can adjust the ambient setpoint by ±5°C

on the control panel .

Summary of Contents for MURELLE 110 BOX ErP

Page 29: ...29 5 EXPLODED VIEWS FOR SPARE PARTS...

Page 30: ...30...