Optika

Operating manual - English

Copyright Silca 2017

35

Note: choosing "Last reading" you start a new key matching function (eg. 2nd, 3rd, 4th... copy)

compared to the original key.

6.2.2

MATCHING FROM "LAST READING"

Last Reading: in Optika’s memory there is always the last key read (regardless of whether the “Key

Search” or "Key matching" functions have been used). Therefore, if with an “original” key the “Key

Search” function had been used to find the corresponding reference, the copy made can be compared

by using “Last Reading”. The same applies if a number of copies made from the same “original” have

to be compared.

The “New Reading” function is used if the “original” key to be compared with the copy was not the

subject of a search or already compared.

ATTENTION: if “Last Reading” has been chosen and a type of key different from that in the memory (e.g. bit and

head stop) is fitted into the clamp, the display shows an anomaly message:

6.2.3

POSSIBLE ERRORS DURING "CUT MATCHING"

ERRORS 13 and 14:

It happens when there isn’t a correct alignment between the two keys in terms of spaces and depths

references. The possible causes could be: keys too different or not compatible.

ERRORS 15 and 16:

It happens when the device SW can’t calculate the average error of spaces and depths of the cuttings.

The possible causes could be: the keys are too different or the gap between the two cuttings is too high.

The message indicates that there is too much difference between the cuts and they cannot be compared

within the limits defined by the program. Check that the two keys compared are similar and repeat the

procedure, if necessary. If the error remains try comparing the original key and copied key turned 180°.

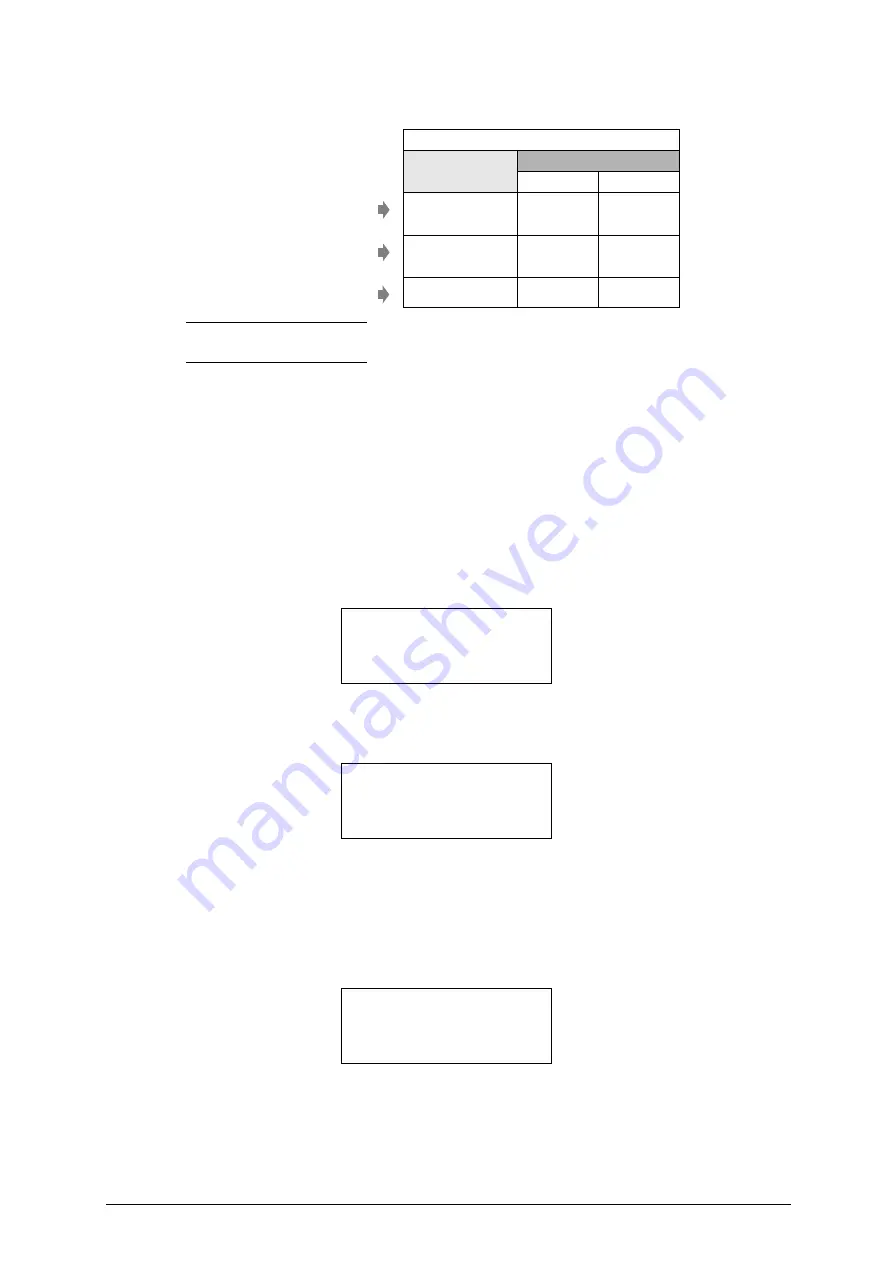

MATCHING TYPE

Values table

(0,01mm)

BIT KEYS

spaces

depths

Standards set by Silca

Cannot be edited

FINE

+/- 15

(0,006")

+/- 15

(0,006")

Standards set by Silca

Cannot be edited

STANDARD

+/- 25

(0,010)

+/- 25

(0,010")

Values set

or to be set by customer

BY USER

+/- 35

+/- 35

The key type select.

is not equal to

the original key

saved in memory

Cut comparison

is not possible!

Error ...

The cuttings of

the inserted keys

cannot be matched!

repeat the operation