27

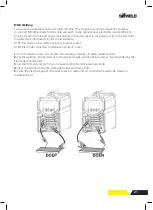

DIAGRAM FOR GUN

23

connectors on the front of the wire feeder.

(4) Connect the gas line to gas connector on the rear panel of wire feeder.

Check for

Leaks!

(5) Connect the control cable of wire feeder with the aero socket on the rear panel of

welding machine.

(6) Connect the cable of wire feeder with the positive output of welding machine.

(7) Connect the water inlet and outlet pipe of wire feeder with the water inlet and outlet

connectors on the rear front of cooling water.

(8) Connect the control cable of cooling water with the aero socket on the rear panel of

welding machine.

(9) Connect the power cable of welding machine with the output switch in electric box on

site.

NOTE:

Air cooling mode without

cooling device

,

and the water pipe is not needed for

the air cooling mode.

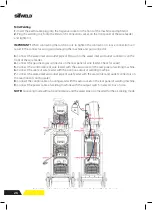

(13) Remove the gas nozzle and contact

tip from the front end of the MIG torch.

(12) Close down the top roller bracket and

clip

the pressure arm into place with a

medium

amount of pressure applied.

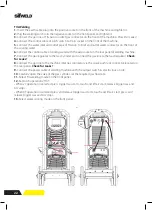

(10) Place wire onto spool holder - (spool

retaining nut is left hand thread) Feed the

wire through the inlet guide tube on to the

drive roller.

(11) Feed wire over the drive roller into the

outlet guide tube, push the wire

through

approx 150mm.

10.

Place wire onto spool holder - (spool retaining

nut is left hand thread) Feed the wire through the

inlet guide tube on to the drive roller.

11.

Feed wire over the drive roller into the

outlet guide tube, push the wire through

approx 150mm.

12.

Close down the top roller bracket and clip the

pressure arm into place with a medium amount

of pressure applied.

13.

Remove the gas nozzle and contact tip from

the front end of the MIG torch.

14.

Press and hold the manual wire key to feed the wire down the torch cable through to the torch

head.

Summary of Contents for Evolution MTS400 SYN

Page 39: ...39 Notes ...