30

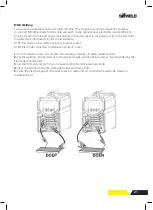

DIAGRAM FOR GUN

26

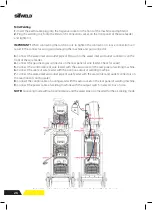

Wire Installation and Set Up Guide

Again the importance of smooth consistent wire feeding during MIG welding cannot be

emphasized enough. The correct installation of the wire spool and the wire into the wire

feed unit is critical to achieving an even and consistent wire feed. A high percentage of

faults with MIG welders emanate from poor set up of the wire into the wire feeder. The

guide below will assist in the correct setup of your wire feeder.

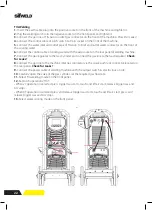

3.5 Wire Installation & Setup

The importance of smooth consistent wire feeding during MIG welding cannot be emphasized enough.

The correct installation of the wire spool and the wire into the wire feed unit is critical to achieving an

even and consistent wire feed. A high percentage of faults with MIG welders emanate from poor set up

of the wire into the wire feeder. The guide below will assist in the correct setup of your wire feeder.

DIAGRAM FOR GUN

26

Wire Installation and Set Up Guide

Again the importance of smooth consistent wire feeding during MIG welding cannot be

emphasized enough. The correct installation of the wire spool and the wire into the wire

feed unit is critical to achieving an even and consistent wire feed. A high percentage of

faults with MIG welders emanate from poor set up of the wire into the wire feeder. The

guide below will assist in the correct setup of your wire feeder.

1.

Remove the spool retaining nut.

2.

Note the tension spring adjuster and spool

locating pin.

3.

Fit the wire spool onto the spool holder fitting

the locating pin into the location hole on the

spool. Replace the spool retaining nut tightly.

4.

Snip the wire carefully, be sure to hold the

wire to prevent the spool uncoiling. Carefully

feed the wire into the inlet guide tube of the

wire feed unit.

Summary of Contents for Evolution MTS400 SYN

Page 39: ...39 Notes ...