10

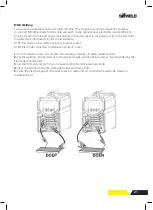

1.4 Overview of Machine

Front View

Power Source Front Panel Layout

1. Negative Output

2. Gas outlet

3. TIG gun control connector.

4. Positive Output

Rear View

5. Gas Inlet

6. Positive Output

7. Wire feeder connector

8. Water Cooler connector

9. Power source input

10. Power switch

PANEL FUNCTIONS & DESCRIPTIONS

5

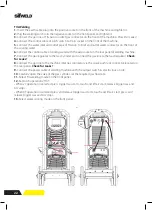

Panel Functions & Descriptions

§ Machine Layout Description

§Front and rear panel layout of welding machine

1. Negative Output

When MIG mode, this polarity must connect the work piece.

2. Gas outlet

: Connect the inlet of TIG gun.

3. TIG gun control connector.

4. Positive Output

: When TIG mode, this polarity must connect the work piece.

5. Gas Inlet

: Connect the gas conduit.

6. Positive Output

: Used to connect to the welding cable of wire feeder.

7. Wire feeder connector

: Used to connect to the control cable of wire feeder.

8. Water Cooler connector

: To connect water box.

9. Power source input

: To connect power source.

10. Power switch

: Turn on power supply clockwise and turn off power supply

counterclockwise.

PANEL FUNCTIONS & DESCRIPTIONS

5

Panel Functions & Descriptions

§ Machine Layout Description

§Front and rear panel layout of welding machine

1. Negative Output

When MIG mode, this polarity must connect the work piece.

2. Gas outlet

: Connect the inlet of TIG gun.

3. TIG gun control connector.

4. Positive Output

: When TIG mode, this polarity must connect the work piece.

5. Gas Inlet

: Connect the gas conduit.

6. Positive Output

: Used to connect to the welding cable of wire feeder.

7. Wire feeder connector

: Used to connect to the control cable of wire feeder.

8. Water Cooler connector

: To connect water box.

9. Power source input

: To connect power source.

10. Power switch

: Turn on power supply clockwise and turn off power supply

counterclockwise.

Summary of Contents for Evolution MTS400 SYN

Page 39: ...39 Notes ...