Hazardous voltage.

Will cause death or serious

personal injury.

Turn off power before working on this

equipment.

3.6 Installation of Seismic Qualified Structures

Siemens TIASTAR MCCs are qualified to withstand seismic

activity as specified in IBC 2006, CBC 2007, and IEEE 693,

2005. This includes all TIASTAR MCCs, all NEMA types and MCC

sizes. TIASTAR MCCs are rated at importance factor 1.5*. The

seismic qualifications include mounting locations from ground

level to roof top.

Installations in seismic qualified structures require two (2)

bearing plates (D67703306) and a lever stop assembly

(D45723001). In addition, to qualify for Level 4 locations,

back-to-back MCCs require reinforced side and divider sheets.

The motor control center should be anchored to the floor with

appropriate hardware and 1/2" bolts. For seismic zone 4 instal-

lations, all mounting holes supplied in the standard base chan-

nel sills must be used. Welding is also an acceptable method of

mounting, if the installation instructions are followed.

3.7 Joining Shipping Sections

Shipping sections consist of up to four vertical frames shipped

as a single unit. It is often necessary to join two or more ship-

ping sections at the job site. All necessary electrical and struc-

tural joining components are provided and the following pro-

cedures are recommended.

1. Position the first shipping section into place on the founda-

tion and level.

2. Remove the front horizontal bus barrier and the side covers

(if applicable) from the end(s) to be joined. If the rear is

accessible, the back cover plates should be removed from

the two adjoining sections.

3. Position the second shipping section on the foundation

adjacent to the first and level it. The horizontal bus should

be inspected for proper positioning and alignment at this

time.

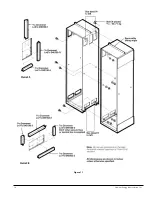

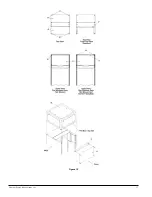

4. Bolt structures together at six points (see Figure 11). If

access to the rear of the structures is restricted, the rear

center bolt may be omitted.

Note:

When aligning different depths of structures (i.e. 15"

front only or 20" deep front only), align the fronts of the

structures and bolt together using front three bolts.

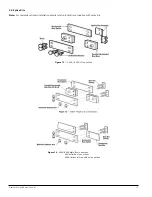

5. Assemble the bus bar links to join the horizontal power bus

and neutral bus, if supplied, in the two shipping sections as

shown on page 16. The horizontal and neutral buses may

differ in size, material, or plating, therefore, the links must

be matched to the proper bars. All links and associated

mounting hardware are provided with the motor control

center.

6. Torque all bus connections to 20 ft. lbs.

7. If the motor control center has interwiring, connect the

interunit wiring between shipping sections.

8. Join the ground bus between the two adjacent sections, if

supplied. The Ground Bus Section in the manual details this

procedure.

9. If there are other shipping sections to be joined, repeat

steps 1 through 8 above.

10. Secure the motor control center to the foundation.

11. NEMA 3R enclosure sections should be securely joined and

sealed to prohibit intrusion of dust and moisture.

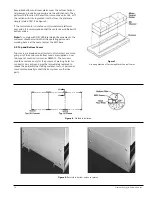

3.8 Ground Bus

All hardware and links are supplied for joining the ground bus

between two shipping sections. This joining may be accom-

plished by loosening the screw securing the connection link so

that the link pivots freely. Remove the screw securing the

ground bus in the adjacent frame to which the link will attach.

Pivot the free end of the link such that the hole is aligned with

the bolt, then reassemble the screw and link assembly. Tighten

hardware. See Figure 10.

Figure 10

- 300A and 600A Horizontal

Ground Bus Connection

Siemens Energy & Automation, Inc.

13

* Importance factor 1.5 identifies components whose post-event oper-

ation is essential to supporting life, safety, and/or if the components

contain materials that would be dangerous to building occupants if

released during an earthquake.