10. If so equipped, the SAMMS panel may be released by loos-

ening the captive screw a few turns, then swinging the

panel to the right to gain access to components mounted

behind it.

11. The drawout unit should be protected from abuse, dust,

and moisture while it is out of the motor control.

12. Latch unit door over open space by rotating the top 1/4

turn latch so that the arrow is pointing up.

3.18 Plug-In Unit Addition

Hazardous voltage.

Will cause death or serious

personal injury.

Energized vertical bus may be partially

exposed through the access holes in the

barrier when the unit is not fully insert-

ed. Use extreme caution when perform-

ing any wiring or maintenance with the

unit withdrawn.

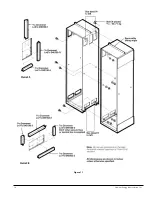

1. Remove the blank door by removing the hinge pins, closing

the door halfway, and pulling it off the hinges.

2. Remove the door gasket angle (intermediate angle) by

removing the screw which fastens it to the separator angle

and tipping slightly to remove the formed tab at top from

the slot in the shelf bracket above.

3. If necessary, install the unit support assembly by inserting

the shelf brackets at a slight angle into the appropriate

holes in the vertical bus support angle and snapping into

place. Secure the support assembly with the two screws

provided. One screw fastens the right-hand shelf bracket to

the vertical bus support angle. The second screw fastens the

separator angle to the left side of the structure.

4. Remove the appropriate unit stab hole covers.

5. Mount the unit door by placing it on the hinges while half

open. Open completely and insert the hinge pins.

6. Plug-In: Move the unit operator handle to the .OFF. position.

Slide the control unit into place on the support assembly.

Complete unit engagement by sliding over the stop on

the shelf brackets with the supplementary installation han-

dle on the bottom barrier plate and closing the racking lever

in the top barrier plate. Engage the multi-turn locking latch

on the bottom plate of the unit to the separator angle and

tighten the screw.

Note:

High density (6.) units do not utilize a multi-turn latch.

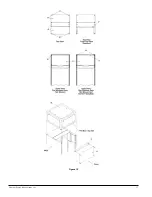

7. Fix mounted: For the location of the panel mounting brack-

ets, see the fixed mounted panel diagram in Figure 53. Use

the bracket with the tab for the top mounting holes.

8. Follow procedures for connecting outgoing power and con-

trol wiring.

9. Close the door and perform all pre-operation check proce-

dures.

Figure 48

Operating handle in

the “OFF” position

Figure 49

Terminal blocks on

swing plate

Figure 50

- Optional pull apart terminal blocks

Siemens Energy & Automation, Inc.

26

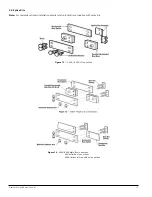

Figure 51

- Padlocking in “test” position

Figure 52

- Fixed Mounted Panel Diagram