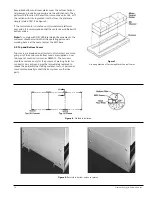

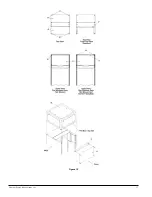

3.4 Mounting

Motor control centers may be mounted by many different fas-

tening systems including true drop in, cast in place, powder

actuated, or threaded insert fasteners. See Figure 6 for anchor

bolt locations. The bolt pattern is dependent on frame width,

depth, location in the line-up. Refer to the structure mounting

detail included on the L1 layout drawing lead sheet. The coor-

dination between bolts and the MCC should be verified prior to

attempting installation. Expandable inserts in predrilled holes

or embedded .L. bolts are recommended. Wooden

plugs driven into holes in masonry or concrete are not recom-

mended for anchoring inserts and should never be used. The

bolt size must be 1/2".

Grouting the sill channels is another method of fastening. This

method requires the foundation to be grooved as shown to

accept the sill channels. See Figure 7 for details.

Welding the steel base or sill channels to a steel floor plate is

an alternate mounting method. See Figure 6 for details.

Note:

Rear top plate can be used for conduit on 20"

deep MCC. Cables can then be run from rear to

front through optional wireway holes to connect

units.

All Dimensions are Shown in Inches.

Shaded Area Indicates Conduit Entry

Figure 5

-

Top Conduit Entry: 15” 20”

Figure 6

-

Anchor Bolt Location and Bottom Conduit Entry: 15” 20”

Siemens Energy & Automation, Inc.

11