9

SE 80/185 T - SE 100/185 T - SE 130/250T

1.0.1- 2008

Tunnel installering

N

Sleipner Motor anbefaler at innstøping av glassfibertunnelen utføres

av kyndig personell. Denne instruksjons manualen gir ikke detaljerte

opplysninger om glassfiberstøpning. Problemer som skyldes instal

-

lering er installatørens fulle ansvar.

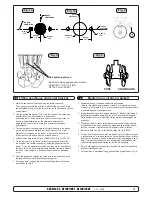

Bestem plassering av tunnelen ut i fra informasjonen gitt tidligere i ma

-

nualen, og de angitte mål for thrusteren du skal installere.

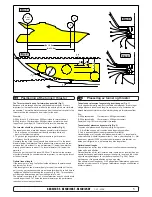

Merk av senter på tunnelen på babord og styrbord side. Bor et 6 m.m.

vannrett hull, på begge sider (Fig. 1).

Bøy til og tilpass en 5 m.m. stålstang, som vist på fig. 2 der den tilbake

-

bøyde enden skal markere tunnelens radius. Stikk enden inn å marker

tunnelens ytre diameter, skjær ut hullet med en stikksag (Fig. 2).

Puss av gelcoat og polyester så glassfiberen ligger bar i et 12 cm stort

område rundt tunnel hullet. Dette må gjøres på innsiden og utsiden av

skroget, før tunnelen støpes fast i skroget (Fig. 3).

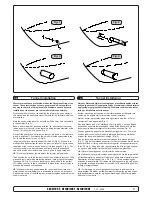

Sett inn tunnelen å marker hvor det skal kappes for å passe i skroget

(Fig. 4). Hvis det skal støpes en spoiler i forkant av tunnelen bør en del av

tunnelen stikke ut i for og underkant av skroget for å støpe spoileren mot

(Side 20, Fig. 2). Kapp tunnelen i ønsket størrelse. Slip lett med slipepa-

pir, og vask med aceton der hvor det skal støpes med glassfiber.

NB ! Det må ikke støpes der hvor thrusteren skal monteres.

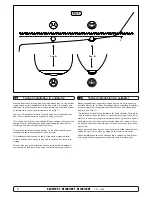

Støp fast tunnelen først på innsiden av skroget, bruk minst 8 lag med 300

g Glassfibermatte, og polyester. Ved bruk av alternative materialer, glass

-

fiber matter eller rovingtyper (Se s. 20, Fig. 1). Hvis tunnelåpningene

avrundes til den optimale 10% radius må ofte legge ekstra lag med polyes

-

ter glassfibermatte på innersiden av tunnelen, for å oppnå riktig tykkelse i

forhold til skrogtykkelsen.

NB ! Forsikre deg om at overgangene mellom tunel og skrog er nøye

sammenstøpt. På steder en ikke kommer til med vanlige lag med polyes-

ter/glassfiber matte, sørg for og lage en blanding av polyester og glass

-

fiber, som fylles i dette.

Tunnel installation

R

D

Fig. 1

Fig. 3

Fig. 4

Fig. 2

GB

We recommend that a professional does the fibreglass fitting of the

tunnel. These instructions are only general, and do not explain in

any way the details of fibreglass work. Problems caused by faulty

installation of the tunnel, are the installers full responsibility.

Find the position in the boat considering the information given earlier in

this manual and the applicable measurements for the thruster model you

are installing.

Mark the centre of the tunnel on both sides. Drill a 6mm hole horizontally

in these marks (Fig. 1).

Bend a ø 5mm steel bar as shown with the “tip” bent back at the tunnel

radius and mark the circle for the tunnel opening (outside diameter of the

tunnel). Cut the hole with a jigsaw (Fig. 2).

Grind off the gelcoat and polyester so that you are down in the “real fibre

-

glass” in an area of 12cm around the hole both inside and outside in the

hull to cast the tunnel to the hull (Fig. 3).

Insert the tunnel and mark its shape to fit the hull (Fig. 4). (if you are in

-

stalling with a deflector/spoiler, leave a part or the tunnel of the front- and

underside of the tunnel to have a base for this (see page 20, Fig. 2). Cut

the tunnel ends to the desired shape and lightly sand its surface and

clean with acetone or similar where you are going to apply fibreglass.

NB! Do not cast/glass on the area were the thruster will be placed.

Then cast the tunnel to the inside of the hull, use at least 8 layers of 300 g

glass and resin, preferably alternating mat and rowing types of fibreglass

(see page 20, Fig. 1). If you are rounding the tunnel ends to the perfect

10% radius you may in some cases have to make further layers inside to

preserve the desired hull thickness.

NB! Make sure that any gap between the tunnel and the hull are com-

pletely filled with resin/fibreglass. In areas where you can not access to

make normal layers of resin/fibreglass, a resin/ fibreglass mixture must be

filled in that area.