22

SE 80/185 T - SE 100/185 T - SE 130/250T

1.0.1- 2008

Before seeking assistance at the help desk of your Sidepower dealer/distributor please perform these tests and make notes of

all measurements to ensure that they have as much information as possible to work on.

NB! All check points and solutions must be carried out after consulting the relevant information elsewhere in this manual to under-

stand how the system is intended to work. If you are unable to understand what to check, you must consult a professional.

Trouble shooting

GB

Solution

Check the flexible coupling/shear pin and the motor installation to ensure correct con

-

nection of the flexible coupling before re-fitting the electromotor.

Re-fasten or replace the propeller and/or key/drive pin.

In case of a failure inside the gearhouse, we advice to get a replacement gear-house

instead of attempting to repear the internal gear and bearing system.

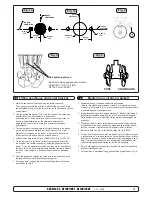

If wrong, contact your dealer or distributor to obtain parts with the correct voltage.

The no load voltage should be:

12V system =12,7V / 24V system = 25,4 V. If below 12,3V / 24,6V your batteries are

not in a good charge state or worn out and must be recharged or replaced before trying

to run the thruster.

If less than 8,5V at the thruster the voltage is to low for the thruster to operate correctly.

In a 24V boat the thruster will operate down to approx. 12V, but the performance will

be very bad. Find and correct the reason for this low voltage which will probably be

one or more of these points: main battery cable sizes and connections, battery size and

condition, fuse and main power switch performance.

If the thruster runs in both directions, try the same in the connector that goes into the

back of the control panel. If it also works in this position, check the contact and wires

on the back of the panel and try to engage this again by pushing both ON buttons

simultaneously. If the panel does not turn on (see control light), measure the voltage

between the Red and the Black in the contact going into the thruster. If the voltage is

good, chances are that the panel is not working.

If it works by the thruster, and not by the panel there is a bad contact or a broken lead

the control cables between these two test points.

Measure that you have the correct voltage between the Red (+) and all the other col-

ours in the contact. If you do not get a reading.

Between main minus (A1 on motor) and the blue and the grey wire connected to the

sides of the main solenoids you should have the same voltage as between

the main battery cables on the thruster. If not, check that the internal wiring on the so-

lenoid is ok and measure that there is contact through the magnetising spools of each

side of the solenoid (measure between the red and blue on one side, and red and grey

on the other side with an Ohm meter.). If there is no

contact between these, the solenoid is broken and needs replacing.

If less than 10,5 V / 21V the thruster will not perform at specified effect.

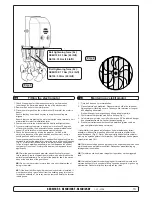

If one or more brushes are loose/has no tension from the brush-spring, the perfor-

mance will be low.

If there is growth in the tunnel, this will disturb/block the waterflow and especially bar

-

nacles on the propeller will greatly reduce performance.

Re-charge battery(ies), if this is not sufficient, replace battery(ies).

Check for bad cable connections, if necessary tighten/re-adjust connections.

Check cable size in accordance to manual.

Shut off thruster main switch, tap slightly on the solenoid to see if it will release. Turn

on thruster main switch. If solenoid is still in lock-in mode, replace solenoid.

Check

If the flexible coupling between the motor and driveshaft is

not fitted correct inside the boat.

Are the propellers in the tunnel fastened correctly on the

prop-shaft (key/drive pin present)

With the motor removed, turn the driveshaft from inside

the boat to feel if the gears are engaging and turning the

prop-shaft.

Check that the voltage of the electromotor is correct for

your installation by their labels.

Check the voltage at the thruster between main minus input

(A1 on motor) and main plus input point:

Check the voltage at the thruster while you are trying to

run it. Keep main engine(s) running to have continous

charge to the batteries.

If the main solenoids on the thruster are not even trying to

engage (clicking) they are probably not getting a "run" sig-

nal from the control system. Try to run the thruster without

the panel by directly connecting the red and the blue or the

red and the grey wires in the controlcable contact coming

from the thruster.

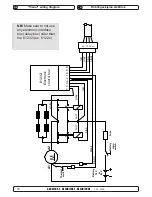

If the thruster does not run at all, or only in one direction in

the above tests, check the internal wiring on the thruster

motor, solenoids and electronic motor inter-face box to be

in accordance with the wiring diagram and ensure that all

connections are clean and tight.

Check voltage at thruster when running.

Check that all the brush-springs sits correctly on the brus-

hes in the electromotor.

Check that the propeller, gearhouse and tunnel is free

from growth/barnacles etc.

Solenoid flapping, most probable cause:

low voltage.

Solenoid lock-in, auto stop of thruster, auto retry every 10

seconds.

»

The electromotor runs, but there is no thrust.

»

The thruster does not start at all or works only in one direction.

»

The thruster has an unexpected low performance.

»

The thruster runs for approximately 0,5 seconds every 4 seconds.

»

The thruster runs for approximately 0,5 seconds every 10 seconds.