15

SE 80/185 T - SE 100/185 T - SE 130/250T

1.0.1- 2008

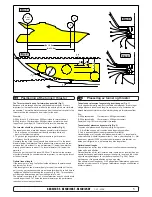

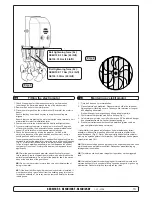

Kontrollpanel og kontrollkabler

Kontrollpanel installasjon:

• Alle standard ”Sidepower” panel for 1999 modeller og senere kan

brukes i enhver kombinasjon med hverandre.

• Alle fireleders, toveis kontrollbrytere kan også brukes hvis de er utstyrt

med en ”av og på” bryter for som bryter strømmen til bryteren.

• Det er mulig å installere så mange kontrollpanel som ønskelig ved å

bruke ”Sidepower” Y-stykker.

• Hvis thrusteren skulle motta flere forskjellige signaler samtidig så kutter

den til den mottar kun et signal fra et kontrollpanel.

• Ved bruk av Sidepower originalutstyr er alle elektriske kontakter klare til

å plugges i sammen.

• Hvis kjøreretningen ikke stemmer overens med forventningene må blå

og grå ledning på Thruster-releet byttes om. For å få til dette må den

elektroniske kontrollboksen snus 180

o

i braketten.

• Alle paneler må ha et fjær oppheng som gjør at de automatisk hopper

til nøytral posisjon etter bruk.

• Monteringsveiledning for panelet følger panelet.

• Thrusterpanelet bør monteres et sted det er lett å bruke. Siden gass og

gir ofte brukes samtidigt som thrusteren, er det ofte en god løsning å ha

muligheten å operere disse med hver sin hånd.

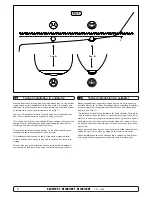

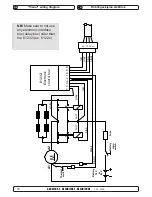

Pinne konfigurasjon for fireleder AMP kontakt:

Pinne 1: Svart

= Jord

Pinne 2: Blå

= Aktiverer thruster rele Styrbord

Pinne 3: Grå

= Aktiverer thruster rele Babord

Pinne 4: Rød

= Pluss til kontrolpanel

N

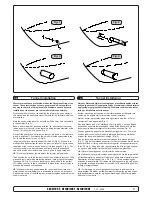

Control panel and control-leads

GB

1

2

3

4

2

1

3

4

Pin 4

Pin 3

Pin 2

Pin 4

Pin 3

Pin 2

M

12 or 24V

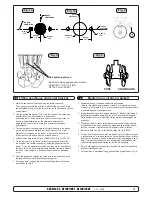

SLEIPNER

SID EPO W ER

THRUSTER

OFF

ON

ON

SLEIPNER

SID EPO W ER

THRUSTER

OFF

ON

ON

Control panel installation:

• All standard Sidepower control panels of 1999 models and later

can be used in any combination as well as any two way

switching device when installed with an ON/OFF switch that

breaks control power to this switch.

• You can install as many panels as you wish by using optional

Y-connectors. If two or more panels are operated at the same

time in opposite directions, the electronic control box will stop the

thruster until it only receives a signal to go in one direction.

• When using original Sidepower equipment it is all “plug & go”.

• If the drive direction of the thruster is the opposite of what

expected, the blue and grey wire must be changed on the thruster

solenoid. You must turn the electronic control box 180o around in

its clip to do this.

• All controls must have spring load for automatic return to neutral

position.

• The mechanical installation of the panel is described in the

manual following the panel.

• The thruster control should be placed in a position were it is easy

to use, and it is very common to use the thruster at the same

time as your gear/throttle lever so it is normally a user friendly

solution to be able to access these with one hand for each

control.

Pin configuration of 4 pole AMP contact:

Pin1:

BLACK

=

Ground

Pin2:

BLUE

=

Engages thruster SB solenoid

Pin3:

GREY

=

Engages thruster Port solenoid

Pin4:

RED

=

Positive voltage for control panel