14

SE 80/185 T - SE 100/185 T - SE 130/250T

1.0.1- 2008

Model

Voltage Nominal

current

draw

Min. battery

CCA

>7m total + & - 7-14m total + & - 15-21m total + & - 22-28m total + & - 28-35m total + & - 36-45m total + & -

Min.

Rec. Min.

Rec.

Min.

Rec.

Min.

Rec.

Min.

Rec.

Min.

Rec.

SE80/185T

12 V

530 A

DIN: 550

SAE:1045

mm

2

AWG

60

2/0

70

2/0

95

3/0

2x 70

2x 2/0

2x 70

2x 2/0

2x 95

2x 2/0

2x 95

2x 3/0

270*

2x 120

2x 4/0

340*

NA

NA

24 V

260 A

DIN: 300

SAE: 570

mm

2

AWG

25

1

35

1

35

1

50

1/0

60

2/0

70

2/0

70

2/0

95

3/0

95

3/0

120

4/0

120

4/0

2x 95

2x 3/0

SE100/185T

SE130/250T

12 V

740 A

DIN: 750

SAE: 1425

mm

2

AWG

95

3/0

95

3/0

2x 70

2x 2/0

2x 95

2x 3/0

2x 95

2x 3/0

280*

250*

375*

NA

NA

NA

NA

24 V

340 A

DIN: 400

SAE: 760

mm

2

AWG

35

1

50

1/0

50

1/0

70

2/0

60

2/0

95

3/0

95

3/0

120

4/0

120

4/0

2x 95

2x 3/0

2x95

2x 3/0

2x 120

2x 4/0

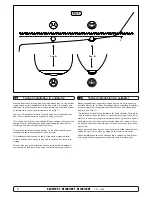

Minimum and recommended cable dimensions can be identical due to safety margins and cable heat considerations for short cable lenghts.

* Minimum or recommended cable cross section in mm

2

Battery & cable recommendations:

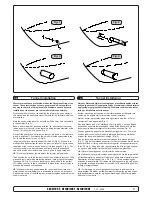

Elektrisk installasjon

N

•

Forklaring til elektrisk tabell

- Kabellengder til kabelen, og - kabelen (Frem og tilbake).

- Min. batterikap. som kaldstartkapasitet (CCA), ikke Ampere.

- Bruk trege sikringer for å forebygge spenningsfall.

•

Det er viktig å bruke kabler som er store nok, og et batteri med god ka-

ldstartkapasitet for å drive thrusteren. Det er Volten som kommer frem

til motoren under kjøring som bestemmer turtallet til motoren og dermed

også skyvekraften. Vær vennlig og jamfør listen over for minimum

anbefalte kabel, og batteristørrelse.

•

En hovedstrømbryter (*C) som ikke medfører stor spenningsfall må

installeres på thrusterens plusskabel. Det bør være mulig å skru av

strømmen til thruster uavhengig av resten av det elektriske systemet,

når man ikke er om bord, eller i et nødstilfelle. Bryteren bør plasseres

på et tilgjengelig sted, og båtens instruksmanual må ta for seg at denne

skal skrus av slik som de andre hovedbrytere.

•

Det må installeres sikring på pluss strømkabelen for å beskytte mot

kortslutning av hovedstrømkablene. Sikringen bør være av høy kvalitet,

noe som vanligvis betyr at de er fysisk store, for å unngå spenningsfall

som ofte er resultatet av å bruke mindre, enklere sikringer. Sikringen

skal være en treg type som tåler amper trekket til elektromotoren i

minimum 5 min.

•

En kretsbryter kan erstatte sikringen og hovedstrømbryteren hvis den

har de samme funksjonene.

•

Kabelendene kan må påmonteres terminaler og disse må isoleres mot

alt som ikke er riktig kontaktpunkt.

•

Det er viktig att kabelsko trekkes korrekt fast på koblingsbolt. Kontra

mutter på koblingsbolt må holdes fast ved tiltrekking (Fig. 2).

Minus kabelen (*A) tilkobles A1 (-) terminalen.

Pluss kabelen (*B) tilkobles "+" terminalen.

ø10mm / 3/8’’på motoren dra til med 15 Nm.

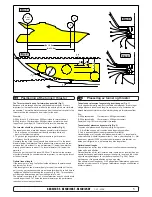

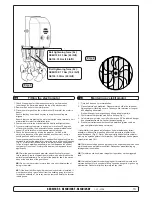

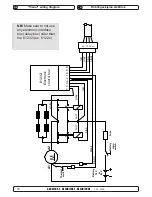

Electrical installation

GB

Battery

12V or 24V

+

-

M

-

+

*D

*C

Fig. 1

Fig. 2

•

Explanation of electrical table

- All cable lengths are the total of + and - (to and from).

- Battery size is stated as minimum cold crank capacity, not Ah.

- Use slow fuse rated to hold stated Amp-Draw for min. 5 minutes.

•

It is important that you use a good cable size and batteries with a

high cranking capacity to feed the thruster, because it is the actual

voltage at the motor while running the thruster that decides the

output rpm of the motor and thereby the actual thrust. Please see

the list below for advised min. sizes of cables and batteries. You can

of course use larger cables for even better results.

•

A main switch (*C) that can take the load without noticeable voltage

drop must be installed in the main positive lead so the power for the

thruster can be turned off independent of the rest when not on board

or in emergencies. This should be placed in an easy accessible

place and the boats instructions should inform that this should be

turned off like the boat’s other main switches.

•

We also advice to install a fuse (*D) in the positive lead for protection

against short circuiting of the main cables. This fuse should be of a

adequate quality which normally means that it is physically large as

these have less voltage drop than the simple / small ones. It should

be of the slow type and sized to take the amperage draw for at least

5 minutes.

•

A circuit breaker can be used instead of the fuse and main power

switch as long as the functionality is the same.

•

The cable ends must be fitted with terminals and these must be well

isolated against contact with anything but the proper connection

point.

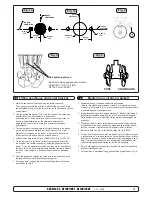

•

Terminals must be properly tightened. Secure/hold inner nut when

tightening (Fig. 2). Tighten with max: 15 Nm/11lb/ft.The negative/

minus cable (*A) connects to the A1 (-) terminal. The positive/plus

cable (*B) connects to the “+” terminal: ø10mm / 3/8"

bolt. Tighten with 15 Nm/11lb/ft.

NB! Very important to check the following with mainswitch

in off position:

After all electrical connections have been completed check with an

ohm meter that there is no electrical connection between electro-

motor body and positive terminal on the motor and between the

electromotor body and the negative (A1) terminal on the motor.

If you feel unsure on how to perform this check, contact skilled

personnel for guidance.