DA

L

19

65

Page 5/18

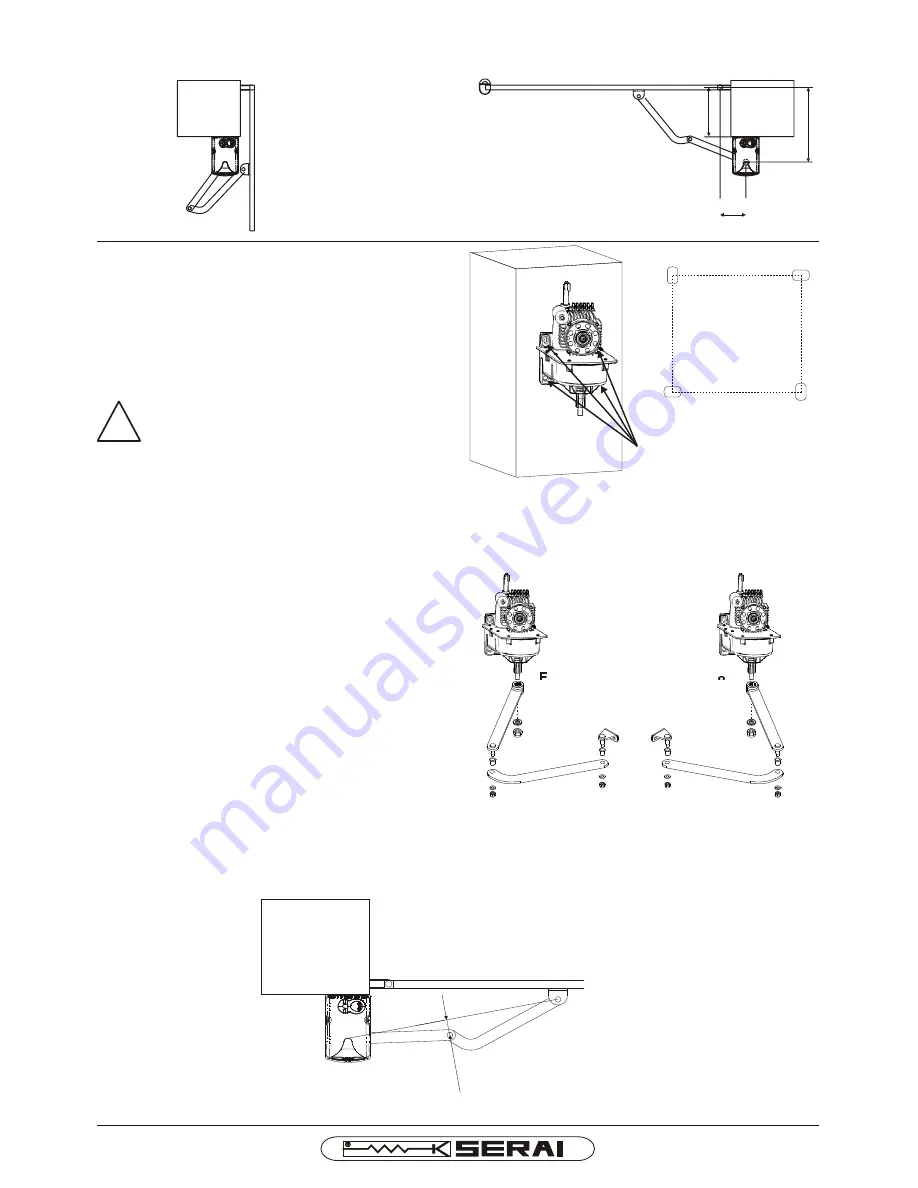

4 MOTOR FIXING POINTS

EXAMPLE FOR GATE INSTALLED TOWARDS THE EXTERNAL PART OF THE PILLAR

B

=

5

1

2

A=160

M

A

X

3

5

0

INSTALLATION

Fig. 5

MOTOR FIXING

POINTS INTERAXIS

3 -

After having defined the position of installation, fix

the motor to the pillar using N°4 M8 screws (hex

head or cylindrical head with recessed hexagon)

complete with large washer (external diameter

24mm) with fixing system suitable for the type of

pillar.

4 -

fig.7-8.

5 -

Assemble the levers, in left and right assembly, only

the position of the curved arm differs while the

straight arm must always be mounted with the pin

downwards, see

Insert the straight lever bush into the toothed outlet

of the shaft and fix it using the nut and washer.

Fig. 7

Fig. 6

Fig. 8

110mm

1

0

0

m

m

6 -

fig.9.

7 -

8 -

9 -

Position the articulated arm bracket on the gate as far away from the column as possible, extending the arms

to maximum and always respecting the measurement of

as indicated in

Fix the articulated arm bracket to the leaf suitably using screws or by welding.

Keeping the motor reducer released, check the correct movement of the articulated arm and of the leaf.

Repeat the same operation for the other leaf.

C

³

100

C

³

100

Fig. 9

K

IT

/A

9

I

E

!

ATTENTION:

- Should pillar be too narrow, e.g. 100mm,

use the plate K/88

- Should pillar be made of light material,

e.g. stones or tuff, the strength of the

motor against the mechanical stops

could be too high for a normal fixing

system and the motor could come off the

pillar. Use in this case a proper fixing

plate