INSTALLATION

2-1 Installation environment

•

Locations free of water droplets, vapors, dust and oily dust.

•

Non-corrosive, flammable gas and liquid.

•

No floating dust metal particles.

•

The environment temperature is -10°C

~

50°C. If the environment

temperature exceeds 40°C, please place it in a well ventilated place

and delete the inverter

•

Strong and vibration-free place.

•

Locations without electromagnetic noise interference.

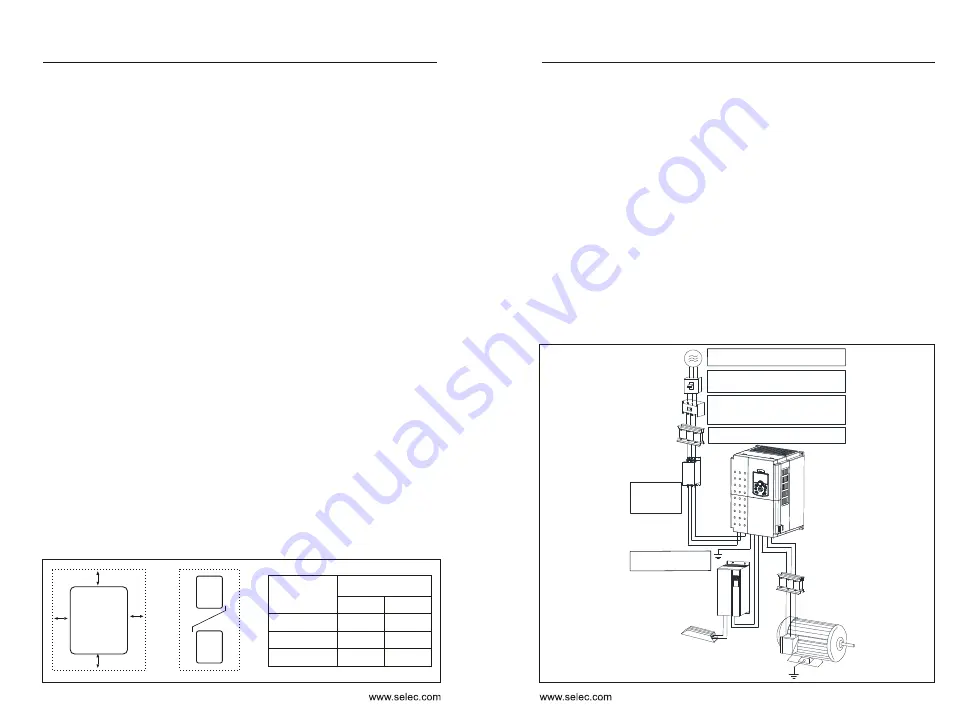

2-2 Installation method and space

•

The inverter should be installed on a structure that does not burn, such

as metal, otherwise a fire accident may occur.

•

The inverter should be installed vertically and securely with screws. Do

not flip, tilt or install horizontally. When the inverter runs, heat is

generated. To ensure the passage of the cooling air, a certain space is

left during installation (as shown in the figure).

•

When installing the inverter in the control cabinet, consider ventilation

and heat dissipation to ensure that the ambient temperature of the

inverter does not exceed the specified value. Do not install the inverter

in a closed box with poor ventilation.

•

When installing multiple inverters in the same control cabinet, it is

recommended to install them side by side in order to reduce the

thermal impact between each other. If it is necessary to install up and

down, a partition plate must be provided to reduce the influence of heat

generated in the lower part on the upper part (as shown in the figure).

•

Do not allow foreign matter such as various fibers, paper sheets, chips

(chips) or metal fragments to enter the inverter.

50mm

50mm

≥

100mm

≥

100mm

UP

Right

CONVERTER

CONVERTER

CONVERTER

User Manual

User Manual

Chapter 2

Chapter 3

7

6

Installation size

Power level

≤

15kw

18.5~30kw

≥

37kw

≥

50mm

≥

300mm

≥

50mm

≥

200mm

≥

20mm

≥

100mm

A

B

WIRING

In order to ensure the safety of operators and inverters, it is

necessary to be operated by qualified professional electricians. The

following are special considerations when wiring :

3-1 Peripheral device connection

•

Make sure the input power is off before wiring.

•

The ground terminal of the inverter must be reliably grounded.

•

Verify that the rated voltage of the inverter matches the AC power

supply voltage.

•

The power cable must be connected to the R, S, and T terminals of the

inverter. The motor cable should be connected to the U, V, and W

terminals. Do not connect the fault. Otherwise, the inverter will be

damaged internally.

•

Confirm that the terminals and wires are reliably connected, and the

screws of the main circuit terminals are secured.

•

Do not touch the main circuit terminals, otherwise there is danger of

electric shock.

Breaker

AC reactor

Electromagnetic

contactor

Noise Filter

Braking Unit

Noise Filter Name

Select the

appropriate

model, the

rated current

is not less than

1.5 times the

rated current

of the inverter

Used to

improve

input power

factor

Instruction

Configuration

Three-phase

power

Braking

unit

(+)

(-)

R

U

S

V

T

W

M

Used to

control power

on and off

Used to

reduce the

radio

interference

generated

by the

inverter

It is optional when

the braking torque

can’t meet the

requirements

of use. It is

suitable for large

inertia load and f

frequent start and

stop.

It is used to

reduce the

radio

interference

on the output

side of the

inverter.

MC

Braking unit

AC output reactor

Braking resistor

Motor

Use within the allowable power supply

specification of the AC drive

Select a proper breaker to resist large

in-rush current that flows into the AC drive

at power-on.

To guarantee safety, use an electromagnetic

contactor. Do not use it to start or stop

the AC drive because such operation reduces

the service life of the AC drive.

Suppress the high order harmonic to improve

the power factor.

Three-phase AC

power supply

Moulded case circuit

breaker (MCCB) or earth

leakage circuit breaker

(ELCB)

Electromagnetic

contactor

AC input

react or

Noise filter on

input side

Reduce the

electromagnetic

interference on

the input side

Reliably ground the motor and

the AC drive to prevent electric

shock.

Braking unit

AC output reactor

Braking resistor

Motor

Use within the allowable power supply

specification of the AC drive

Select a proper breaker to resist large

in-rush current that flows into the AC drive

at power-on.

To guarantee safety, use an electromagnetic

contactor. Do not use it to start or stop

the AC drive because such operation reduces

the service life of the AC drive.

Suppress the high order harmonic to improve

the power factor.

Three-phase AC

power supply

Moulded case circuit

breaker (MCCB) or earth

leakage circuit breaker

(ELCB)

Electromagnetic

contactor

AC input

react or

Noise filter on

input side

Reduce the

electromagnetic

interference on

the input side

Reliably ground the motor and

the AC drive to prevent electric

shock.