P3-02

User Manual

User Manual

81

80

The parameter above is used to set transmission rate of the data between

superior controller and converter.

Note: the Baud rate of superior controller and converter should be the same;

therwise, communication cannot be conducted.

The data format of superior controller and converter should be the same;

otherwise, communication cannot be conducted.

9600

Factory default

Baud rate

No checking: 8-N-1

Data format

Factory default

The data format of superior controller and converter should be the same;

otherwise, communication cannot be conducted.

1

P0-15

Factory default

Factory default

Setting range

1-127 (Zero stands for broadcast address)

For other relevant functional parameters, Please refer to P5-25 ~ P5-29

instructions.

9.6 Parameter description of communication

Fault address

Data Description

Register

address

Address

S/N

0xF1

242

1: Storage fault

3: Undervoltage

4: Overvoltage

5: Overload

6: Overcurrent

7: Input default phase

8: Output default phase

9: Output short circuit

10: System fault

11: External fault

12: PI fault

13: Overtemperature

14: Overcurrent

15: Motor Overload

16: Contactor OFF

20: Signal failure of current

detection

21: Communication Fault

Function

Code

Description

Description and Range

Default

P0-01

Frequency

setting

mode

0 : Frequency setting (UP/DOWN)

1 : Panel potentiometer

2 : External AI1

3 : External AI2

4 : PI regulation

5 : UP/DOWN by the P5-20

add and subtract

6 : UP/DOWN by the P5-20 add and

subtract, frequency qing zero downtime

7: Frequency communication reference

0

P0-02

Control mode

for

running

0

0 : Controlled by keyboard

1 : Controlled by terminals,

STOP Key disabled

2 : Controlled by terminals,

STOP Key enabled

3 : Controlled by communication

For a given frequency of communication, you can set P0-01 =7 and the

corresponding address is 1003 (decimal). If it is given in other ways,

please set it as required.

Start and stop the frequency converter through communication,

the corresponding address is 200 (decimal)

P0-15

Modbus address

1

1~247

The uniqueness of the local address is the basis for the point-to-point

communication between the host computer and the converter

P5-25

Communication

baud rate

5

2 : 1200BPS

3 : 2400BPS

4 : 4800BPS

5 : 9600BPS

6 : 19200BPS

7 : 38400BPS

This parameter is used to set the data transmission rate between the upper

computer and the frequency converter. Note that the baud rate set by the upper

computer and the frequency converter must be consistent, otherwise the

communication cannot be carried out.

P5-26

Modbus data

format

0

1 : No check (8-n-2)

0 : No check (8-n-1)

3 : odd parity (8-o-1)

2 : Even parity (8-e-1)

the data format set by upper computer and frequency converter must be consistent,

otherwise, communication cannot be carried out.

P5-27

Modbus response

delay

20

0 ~ 200ms

Refers to the interval time between the end of data receiving of the inverter and data

sending to the uploaded. If the response delay is less than the system processing

time, the response delay shall be subject to the system processing time. If the

response delay is longer than the system processing time, the system shall delay

and wait after processing the data until the response delay time is reached before

sending the data up to the computer

P5-28

Serial

communication

timeout

0.0

0.1

~

60.0s

0.0: invalid (not detected)

P5-29

Communication

abnormal action

selection

0

0 : continue running

1 : alarm and shutdown

When the function code is set to P5-28 = 0.0s, the communication timeout

parameter is invalid. When the P5-28 function code is set to a valid value, if the

interval between one communication and the next communication exceeds the

communication timeout, and P5-29 = 1, the system will report a communication

failure error (CE) and stop. Typically, it is set to invalid. If you set this parameter on

a continuously communicating system, you can monitor the state of communication

This parameter only takes effect when the motor is running above the

rated frequency. When the motor needs to accelerate to 2 times the rated

motor frequency and the actual acceleration time is longer, reduce P2-21

appropriately; when the motor runs at 2 times the rated frequency and the

speed drops greatly, increase P2-21 appropriately. Generally no need to

change.

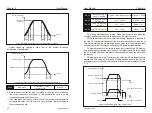

V/F Curve

setting

0: Straight line V/F

1: Multi-point V/F

2: square V/F

3: 1.2 power V/F

4: 1.4 power V/F

6: 1.6 power V/F

8: 1.8 power V/F

9: reserved

10: V/F complete separation mode

11: V/F semi-separation mode

Default

:

0

P3-00

P3: V/F control parameter

This group of function codes is valid only for V/F control and invalid for vector

control. V/F control is suitable for general-purpose loads such as fans and

pumps, or an inverter with multiple motors, or applications with large

differences in inverter power and motor power.

Assuming that the voltage source input is X (X is 0~100%), the

relationship between the inverter output voltage V and the frequency F is:

V/F=2 * X * (motor rated voltage) / (motor rated frequency)

0 : Straight line V/F. Suitable for ordinary constant torque loads.

1 : Multi-point V/F. Suitable for loads such as dehydrators and centrifuges.

Set the P3-03~P3-08 parameters to get any V/F curve.

3~8: V/F relationship between straight line V/F and square V/F.

11 : V/F semi-separation mode. In this mode, V is proportional to F, but the

proportional relationship can be set by P3-13, and the relationship

between V and F is also related to the rated voltage and rated frequency

of the motor of P1 group.

2 : square V/F. Suitable for centrifugal loads such as fans and pumps.

10 : V/F complete separation mode. At this time, the output frequency of the

inverter is independent of the output voltage, the output frequency is

determined by the frequency source, and the output voltage is

determined by P3-13. Generally used in induction heating, inverter

power, torque motors and other occasions.

Torque boost

0.0%

(

Auto

)

0.1%

〜

30.0%

depend

Cut-off frequency

of torque boost

0.00Hz

〜

Maximum frequency Default

:

50.00Hz

P3-01

In order to compensate for the low-frequency torque characteristics of the

V/F control, some boost compensation is applied to the output voltage of the

inverter at low frequencies. However, the torque boost setting is too large, the

motor is prone to overheating, and the inverter is prone to overcurrent.

It is recommended to increase this parameter when the load is heavy and

the motor starting torque is insufficient. The torque boost can be reduced

when the load is light.

When the torque boost is set to 0.0, the inverter is automatically torque

boosted. At this time, the inverter automatically calculates the required

torque boost value according to parameters such as the stator resistance of

the motor.

Torque boost cutoff frequency: Under this frequency, the torque boost is

valid. If the set frequency is exceeded, the torque boost will be invalid, as

shown in Figure 6-3.

f1

fb

Output voltage

Vb

Output frequency

V1 : Manual torque boost voltage

Vb :manual torque boost cutoff frequency

Vb : Maximum output voltage

fb : Rated operating frequency

V1

Figure 6-3 Manual torque boost

Multi-point V/F

frequency point 1

0.00Hz

〜

P3-05

Default

:

0.00Hz

Multi-point V/F

voltage point 1

0.0%

〜

100.0%

Default

:

0.0%

Multi-point V/F

frequency point 2

P3-03

〜

P3-07

Default

:

0.00Hz

Multi-point V/F

voltage point 2

0.0%

〜

100.0%

Default

:

0.0%

P3-03

P3-04

P3-05

P3-06

Chapter 6

Chapter 6