29

MPS4264

Section 4: Hardware

In normal, low-vibration environments the control pres-

sure does not need to be continuously supplied to this port

to hold the valve in the measurement mode. Applying

the pressure for 2-4 seconds will cycle the valve into the

measurement mode where it will stay until cycled out using

the Px CTL port. For high vibration environments, or where

it is absolutely critical that the module be held in measure-

ment mode, it is recommended to continuously supply the

pressure to this port to hold the valve in the desired state.

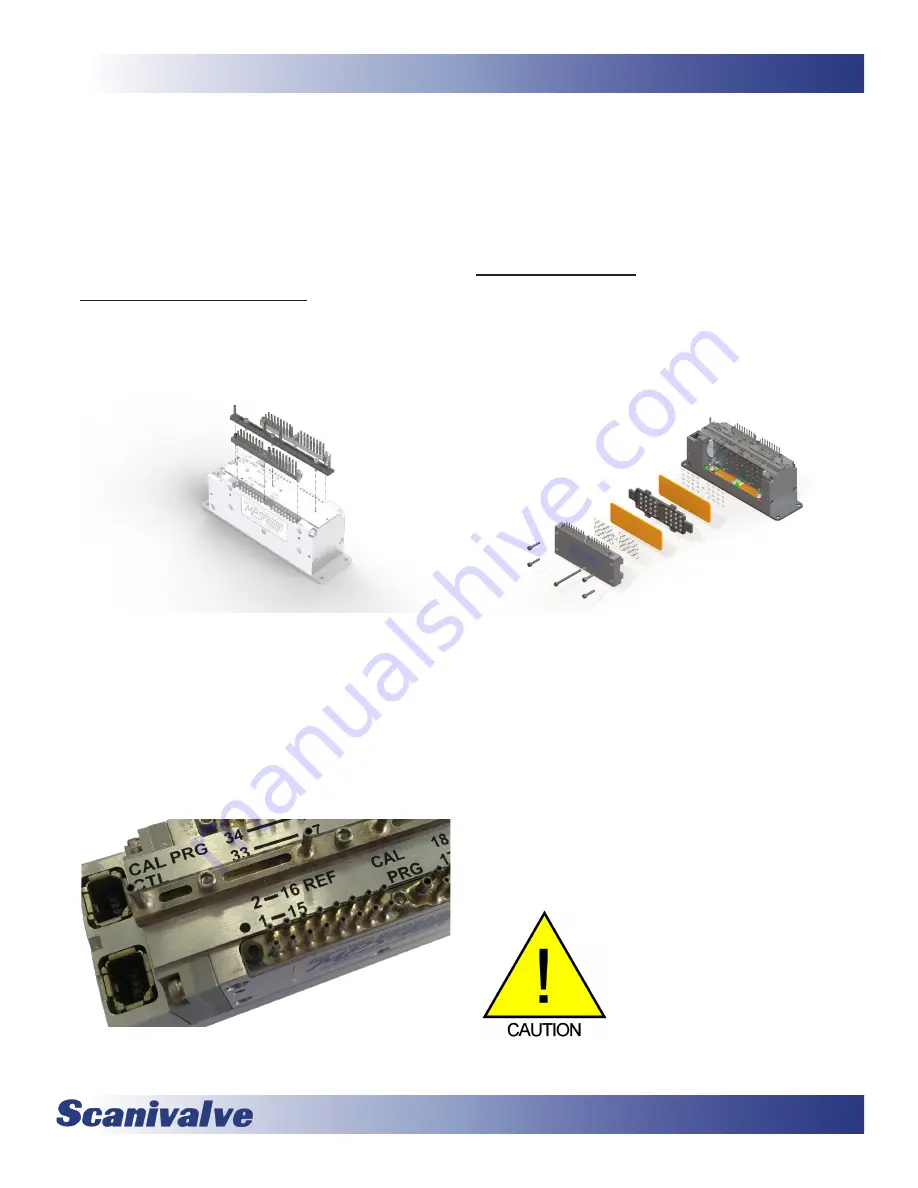

Removable Pressure Input Headers

All pneumatic inputs to the MPS are through three remov-

able input headers. Each of the three headers is held in

place with three #1-72 screws. A 1/16” Allen/hex wrench

fits the screws.

Figure 4-4: Removable Input Headers

The center header is polarized and cannot be installed

backwards. However, the two Px input headers are inter-

changeable and can be installed on the opposite sides. To

keep the manifolds unique and identified, the header for

inputs 1 through 32 has a single black oxide screw, whereas

all of the rest are nickle plated and silver in color. The

“correct” location for the black oxide screw is identified on

the MPS with a solid black dot. See Figure 4-5 below:

Figure 4-5: Header Identifier Mark

Be aware, that when the center header is removed the

identification plate will no longer be held in place. Like

the center header it is indexed and cannot be installed

backwards, but should be handled with care. The O-rings

supported in the identification plate should be kept clean

and watched to make sure they stay in place. Replace-

ment or additional headers can be purchase separately as

needed.

Calibration Valve

The MPS4264 module has two mirrored calibration valves,

each servicing 32 inputs. It is a slider-style valve with the

aluminum shuttle riding on ball bearings. The O-rings that

move with the valve shuttle ride on a proprietary plastic

“bearing plate” that minimizes friction to reduce the actua-

tion force and the wear on the O-rings.

Figure 4-6: Valve Exploded View

The calibration valve has two physical states, “Measure-

ment” and “Calibrate/Purge.” In measurement mode,

measurement pressures from the individual input tubes

is allowed to pass directly through the shuttle valve to the

pressure sensors. In calibrate/purge mode, the measure-

ment pressures from the individual input tubes are blocked

off and isolated from the pressure sensors. Instead, the

“CAL” input is manifolded and connected to the positive

side of all transducers. Additionally, the two “Purge” input

lines are connected to the input tubes on their respective

valves allowing the user to clear debris or moisture from

the input lines by blowing from the module back out to the

test article.

CAUTION! Do not cycle the valve

with pressure supplied to either the

CAL or PRG inputs.

It is uncommon, but possible, that while the valve is

Summary of Contents for MPS4264

Page 1: ...MPS4264 Miniature Pressure Scanner Hardware and Software Manual Software Version 2 07...

Page 2: ......

Page 3: ......

Page 6: ...INTENTIONALLY LEFT BLANK...

Page 12: ...6 MPS4264 Section 1 Specifications INTENTIONALLY LEFT BLANK...

Page 18: ...12 MPS4264 Section 2 Introduction INTENTIONALLY LEFT BLANK...

Page 32: ...26 MPS4264 Section 4 Hardware INTENTIONALLY LEFT BLANK...

Page 38: ...32 MPS4264 Section 5 Software INTENTIONALLY LEFT BLANK...

Page 81: ...75 MPS4264 Section 6 Maintenance INTENTIONALLY LEFT BLANK...

Page 86: ...80 MPS4264 Section 6 Maintenance INTENTIONALLY LEFT BLANK...

Page 87: ...81 MPS4264 Appendix INTENTIONALLY LEFT BLANK...