36

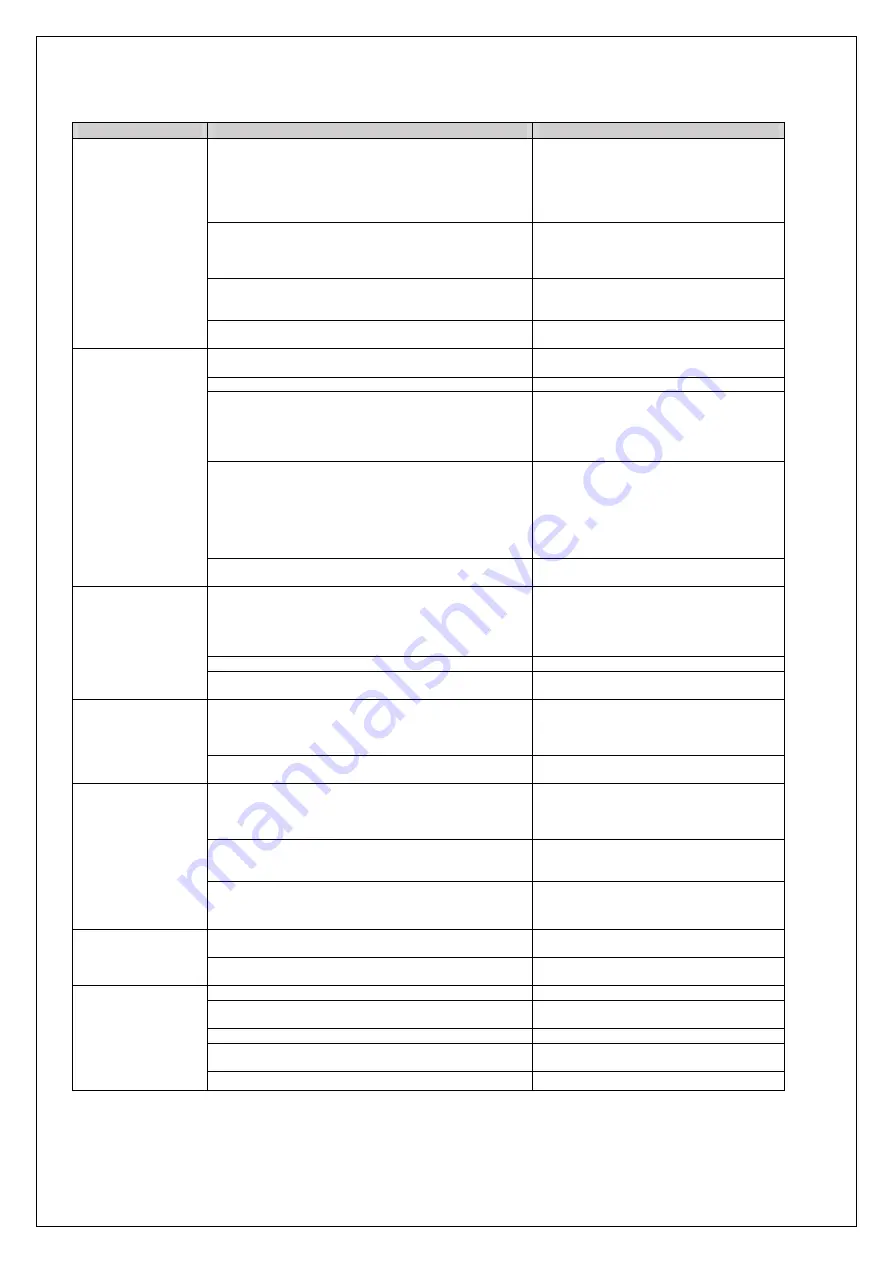

Table 3.2 Drive problems and corrective actions

Problem

Control Mode and Possible Cause

Corrective Action

Rollback at start

Insufficient torque when the brake is released.

• Increase the DC Injection Braking Current at

Start using parameter S1-02.

•Increase Torque Detection Gain (C4-01) in

steps of 0.2.

•Increase starting frequency (S1-00).

•Increase Voltage offset (E1-03) in steps of 5V.

DC Injection and brake timing are not optimized.

Set the time for DC Injection Braking at Start

(S1-04) as short as possible, and make sure that

brake releases completely before the motor starts

to turn.

Motor torque is not fully established when the brake is released.

Lengthen the Brake Release Delay Time (S1-06)

and the time for DC Injection Braking / Position

Lock at Start (S1-04).

Motor contactor closes too late.

Make sure that the contactors are closed before

the Up/Down command is issued.

Shock at start

Motor starts rotating when the brake is not completely released

or runs against the brake.

Increase the DC Injection Braking Time at Start

using parameter S1-04.

Acceleration rate is changing too quickly.

Increase C2-01.

Starting torque influences the calculated slip.

•Increase Slip Compensation Filter Time

Constant (S2-06).

•If the problem exists, increase the Slip

Compensation Delay Time (S2-05) in steps of

50ms.

Starting torque is too much.

•Increase Torque Detection Delay Time (C4-02)

in steps of 50ms.

• If the problem still exists, decrease Torque

Detection Gain (C4-01). Note that decreasing

C4-01 may result in motor stall and over-current

fault. In this case, increase acceleration time

(C1-01).

The starting speed is not optimized.

Change S1-00 in steps of 0.1, and see its

influence on shock.

Shock at stop

Brake is applied too early, causing the motor to run against the

brake.

•Increase the Delay Time to Close the Brake

(S1-07). If necessary, also increase the DC

Injection Braking Time at Stop S1-05.

•If the problem still exists, increase zero speed at

stop (S1-01).

Motor contactor is released before the brake is fully applied.

Check the motor contactor sequence. (S1-11)

DC injection is not powerful enough to stop the motor

efficiently.

Increase DC injection at stop (S1-03).

Jerk occurs due to

overshoot when the

motor reaches top

speed.

Too fast torque or slip compensation.

• Increase the Torque Compensation Delay Time

(C4-02).

• Increase the Slip Compensation Delay Time

(S2-06).

The acceleration rate changes too quickly when reaching the

selected speed.

Decrease the Jerk at the End of Acceleration.

Increase C2-02.

Motor stops shortly

(undershoot) when

the leveling speed is

reached.

Not enough torque at low speed.

If (E1-02=0), change it to 1 or 3.

If E2-02=1, Increase E1-03.

If E2-02=2/3, Increase (E1-10 to E1-13).

Alternatively, you may increase E1-03.

Too much slip compensation.

Adjust the motor data, especially motor rated

speed (S2-01) correctly.

The deceleration rate changes too quickly when reaching

leveling speed.

Decrease the Jerk at the End of Deceleration.

Increase C2-04.

Motor or machine

vibrates at high

speed or top speed.

Torque compensation responds too quickly.

Increase the Torque Compensation Delay Time

(C4-02).

Rated speed is not set correctly

Set the rated speed according to the motor

nameplate.

Motor or machine

vibrates in the low

or medium speed

range.

The output voltage is too high.

Set E2-02 to 2or 3 and decrease E1-10 to E1-13.

Torque compensation is responding too quickly.

Increase the Torque Compensation Delay Time

(C4-02).

The value for the motor slip is set incorrectly.

Check the Motor Slip value in parameter E2-02.

The slip fluctuation is high.

Increase the Slip Compensation Filter Time (S2-

06) in steps of 50ms.

Vibration occurs only in regenerative mode.

Increase C4-01.

Table 3.3 Drive problems and corrective actions (closed-loop)