20

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Disc Brake Servicing

12. Hub Lubrication (Oil)

IMPORTANT:

DO NOT mix oil with grease. If the bearing

assembly has been lubricated with grease,

DO NOT add oil.

Failure to correctly lubricate bearings could

damage bearings which, if not avoided,

could result in death or serious injury.

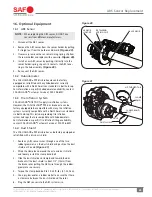

1. Remove plug and fill the hub to the FULL mark with specified

lubricant (oil), through the hole in the hub cap

(Figure 35).

2. Allow the oil to flow through the bearings and level off.

3. Insert the plug into the hole in the hub cap

(Figure 35).

IMPORTANT:

Axles equipped with a centralized tire inflation

system MUST use a vented hub cap.

4. Re-install wheel on hub using support device such as a

wheel dolly jack

.

Failure to support weight during installation

or removal of brake drum could create a

crush hazard which, if not avoided, could

result in minor to moderate injury.

Failure to uncage spring brakes in accordance

with manufacturer’s instructions after

servicing is complete will prohibit proper

brake function which could result in

uneven brake system component wear.

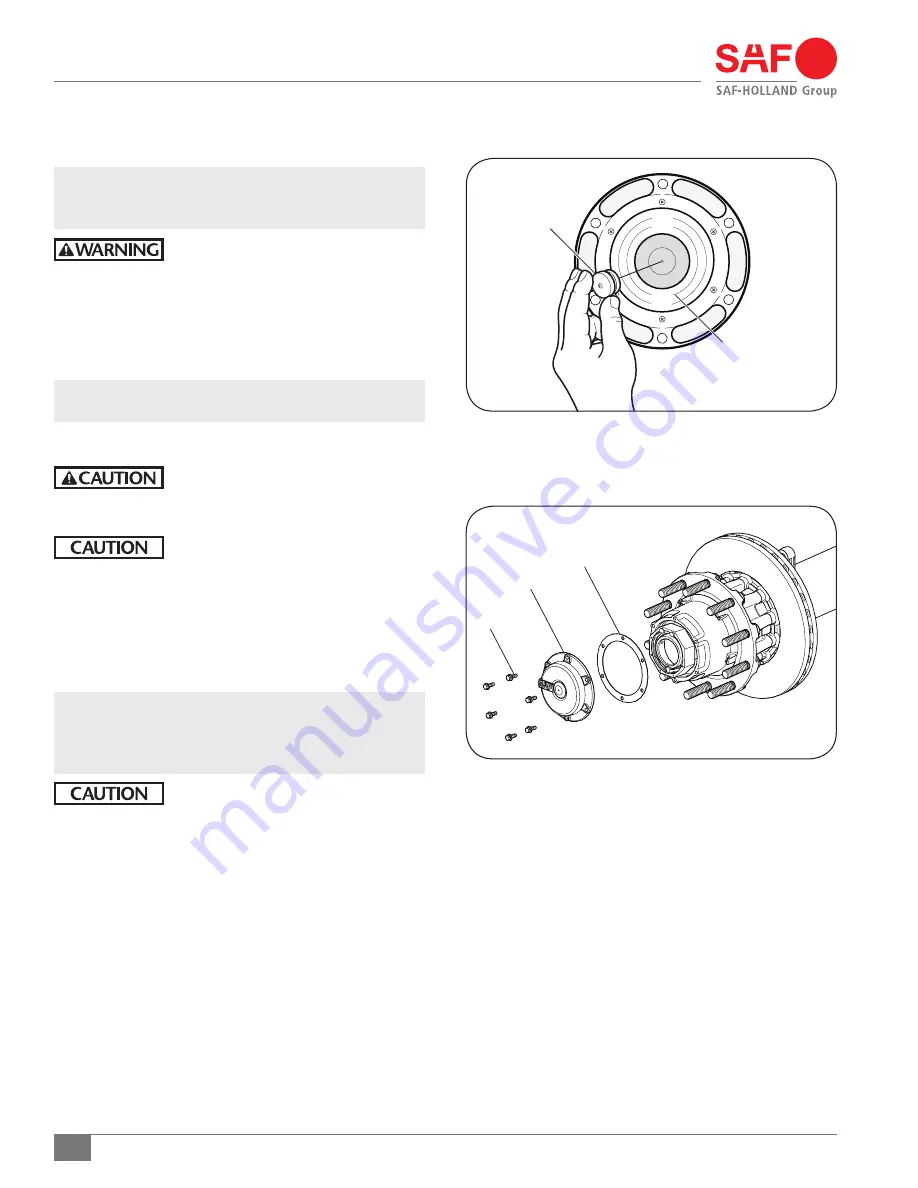

13. Hub Cap Installation

1. Install the hub cap assembly, making sure the hub cap

gasket is in place

(Figure 36)

.

IMPORTANT:

When installing hub cap, make sure the

hub cap gasket is not bent or damaged.

IMPORTANT:

DO NOT over torque. This can crush the

hub cap gasket.

Failure to avoid damaging the hub cap gasket

could allow lubricant to lead which, if not

avoided, could result in bearing failure.

2. Install the six (6) bolts to secure the hub cap assembly

(Figure 36)

. Tighten bolts to 12-16 ft.-lbs. (16-21 N•m).

O

IL

L

E

V

EL

O

IL L

EVE

L

FU

LL

AD

D

FULL

ADD

Figure 35

OIL FILL LEVEL

PLUG

Figure 36

HUB CAP GASKET

HUB CAP

HUB CAP

BOLTS (6)