13

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Disc Brake Servicing

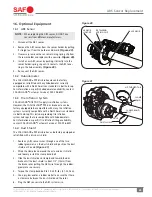

12. Remove the inner hub bearing from the spindle or from

the inside of the hub

(Figure 17)

.

13. The spindle mount hub seal can be driven off the spindle

by striking the ring from the back side or prying off with

a crow’s foot bar. Be careful not to gouge the spindle

shoulder. Discard the used seal. A new seal is required

when re-assembled

(Figure 17)

.

DO NOT use a chisel to cut the seal. The

shoulder can be damaged, resulting in a

leak which, if not avoided, could lead to

wheel end and/or brake failure.

8. Bearing Inspection

Thoroughly clean bearings. DO NOT mix

a synthetic base grease or oil with an

organic/mineral base lubricant.

DO NOT dry hub bearings with compressed

air. Bearing damage could result.

1. After removing the head unit, clean excess grease from

the bearings.

IMPORTANT:

A bearing which has been removed from a

vehicle should be cleaned with solvent. NEVER

use steam or water which will rust bearings.

IMPORTANT:

Bearings that are rusted, flaked, pitted, or

have damaged cages should be replaced. It

is recommended to replace all questionable

bearings and ALWAYS replace the cup and

cone as a matched set.

IMPORTANT:

NEVER re-assemble a tapered roller bearing

in a damaged or worn bearing cup or spindle.

Bearing cup or spindle should be replaced

and NOT re-machined if damaged or worn.

9. Rotor Replacement

Failure to follow these instructions could

cause component failure which, if not avoided,

could result in death or serious injury.

9.1 INTEGRAL

®

Rotor

Refer to pages 6 and 7 for Integral and U-Shaped

Identification. See Section 9.2 for U-Shaped Rotor.

1. Remove the ABS sensor by following the instructions

detailed in Section 16.1.

2. Remove the hub, refer to Section 6 instructions.

3. Remove the rotor from the hub using a size 15 mm

socket to loosen and discard all ten (10) connection bolts

(Figure 18)

.

Figure 17

HUB SEAL

INNER HUB

BEARING