18

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

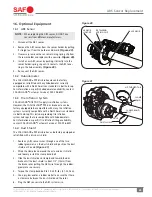

Figure 31

OUTER BEARING

RAISED MARK

PRO-TORQ

®

WHEEL NUT

KEEPER

Disc Brake Servicing

d. Back off the inner axle nut approximately 1/4 turn and

install the axle lock washer

(Figure 30)

. DO NOT

include socket backlash in the 1/4 turn.

e. Install the lock washer. If the hole in the washer is

NOT aligned with the pin on the inner nut, turn the

washer around and re-install. If the pin and hole are

still NOT aligned, slightly adjust parts as needed.

f. Install the outer axle nut finger tight against the axle

lock washer

(Figure 30)

.

g. Tighten the outer axle nut to 200-300 ft.-lbs.

(271-407 N•m).

h. Measure wheel bearing end play (distance wheel

end assembly moves in and out) with a dial

indicator gauge. Wheel bearing end play to be

.001-.005" (.03- .13mm).

NOTE:

if wheel end bearing end play needs adjustment,

remove the outer nut and lock washer, then

tighten or loosen inner nut as needed. Return to

step "6.e".

i. Install the set screw into an accessible threaded

hole in the lock washer. The set screw must contact

the inner adjusting nut. Tighten to 16 - 20 in.-lbs.

(1.8 - 2.2 N•m).

Pro-Torq

®

axle nut

(Figure 31)

:

a. Use a screwdriver to carefully pry the keeper arm

from the undercut groove on each side until the

keeper is released.

b. Seat the bearing. Using a torque wrench, tighten

the nut to 200 ft.-lbs. (271 N•m) and spin the wheel

at least one (1) full rotation. PERFORM THIS STEP

THREE (3)TIMES.

c. Back the nut off until it is loose.

d. Adjust the bearing. Using a torque wrench, tighten

the nut to 100 ft.-lbs. (137 N•m). Spin the wheel

at least one (1) full rotation. PERFORM THIS STEP

THREE (3) TIMES.

e. Back the nut off one raised face mark (1/8 of a turn)

(Figure 31)

.

f. Install the keeper with orange side facing out by

inserting the keeper tab into the undercut groove

of the nut and engage the keyway tang in the axle

keyway. Insert keeper tab with bent legs facing out.

g. Engage the mating teeth of the keeper with the

teeth of the wheel nut.

h. Compress and insert the keeper arms, one at a

time, into the undercut groove with a screwdriver.

i. If the keeper teeth DO NOT line up with teeth in

nut, loosen the nut slightly until they engage.

Figure 30

AXLE LOCK WASHER

OUTER AXLE NUT