16

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Figure 24

HUB SEAL INSTALLATION TOOL

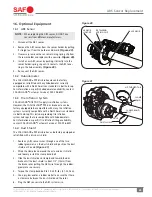

Figure 25

INNER BEARING CUP

OUTER

BEARING CUP

INNER BEARING

DISC HEAD UNIT

DISC SPIDER

Disc Brake Servicing

3. Thoroughly clean the spindle and spindle threads of rust,

dirt, grease or any other contaminants that could damage

the hub seal and cause it to leak.

NEVER install a spindle mounted wheel

seal in the hub and then force it onto the

axle spindle by tightening the axle nut.

Damage to seal will result.

To avoid damaging the seal, support the hub

against the spindle inner shoulder until the

outer bearing and adjusting nut are installed.

4. Apply a thin layer of sealant to the O.D. of the spindle

shoulder. Place the wheel seal on the spindle with the

side labeled “oil-bearing side” facing out towards the

end of the spindle

(Figure 23)

.

5. Seat wheel seal into place using a hub seal installation tool and

hammer. Rotate the wheel seal installation tool 1/4-turn with

every hammer tap until the seal is properly seated with the

metal face of the seal flush with the inner shoulder of the axle

spindle

(Figure 24)

. Clean and remove any excess sealant.

6. Prepare the hub. Remove the old lube and thoroughly clean

the hub cavity and hub bore. If needed, use emery cloth

to remove any burrs or old bore sealant. Inspect the hub

bore for damage. Replace if necessary.

7. Install new inner and outer bearing cups into the hub as

necessary

(Figure 25)

.

8. Install inner bearing on spindle

(Figure 25)

.

NOTE:

If using oil for lubrication, coat bearings with oil

before installation. Refer to Section 12 for proper

wheel end oil lubrication instructions

(Figure 27)

.

Failure to lubricate bearing correctly and

maintain proper lubrication could result in

bearing damage.

NOTE:

If using grease and NOT oil for hub lubrication, the

inner and outer bearing, and the hub cavity MUST be

pre-packed with grease before installation. Lubricate

wheel end components with grease specified in Section 17.

9. Lubricate inside of hub cavity and install on spindle

(Figure 25)

.

NOTE:

Be sure wheel seals are properly installed before

performing the hub bearing adjustment procedure.

Figure 26

INNER BEARING

HUB BEARING CUP

DISC HEAD UNIT