17

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

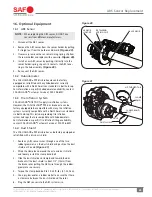

Disc Brake Servicing

11.2 Hub Mounted Wheel Seal Installation

Instructions (Refer to 11.1 for spindle

mounted seal installation)

1. Remove all burrs from the hub bore and spindle. Thoroughly

clean hub cavity and spindle.

NOTE:

DO NOT apply any sealant to the spindle shoulder.

2. Place the hub on a smooth, hard surface in a horizontal

position. Pre-lube the inner bearing and place it into the

hub bearing cup

(Figure 26)

.

NOTE:

When using grease, pre-pack the inner bearing

before placement into the hub.

3. Place the wheel seal on the installation tool, make sure

that the words “oil-bearing side” faces the inner bearing.

Position the tool (with the seal correctly mounted in the

tool head) into the hub bore. Use a three to five pound

hammer to drive against the end of the tool. Drive seal

into bore until complete bottoming is assured

(Figure 27)

.

Remove the installation tool and apply a thin layer of

lubricant on the I.D surface of the seal.

NOTE:

DO NOT apply lubricant to the O.D. of the seal.

11.3 Hub Installation and Bearing Adjustment

1. Gently push the head unit onto the spindle to the proper

position. Fill the hub cavity with lubricant until it runs

over the outer bearing cup.

NOTE:

When using grease, pre-pack the hub cavity. The

grease fill amount should be to a 3 o’clock and

9 o’clock level. This is to ensure a 50% hub cavity

fill. Use a template to hold grease in place while

filling the hub cavity

(Figure 28)

. 3shoulder. This

could damage the wheel seal.

2.

Coat the outer bearing with

lubricant and place the outer bearing

on the spindle and into the bearing cup

(Figure 28)

.

Install outer bearing on spindle.

3. Install the axle nut(s)

Three (3) piece axle nut:

a. Install the bearing inner-axle adjustment nut finger

tight against the outer bearing

(Figure 29)

.

b. While rotating the hub assembly, tighten the inner

axle adjustment nut to 200 ft.-lbs. (271 N•m).

c. Back off the inner axle adjustment nut one full turn

and then re-torque the nut to 50 ft.-lbs. (68 N•m)

while rotating the hub assembly.

Figure 28

PRE-PACK OUTER

BEARING WITH GREASE

PRE-PACK HUB CAVITY

WITH GREASE

GREASE LEVEL

TEMPLATE

Figure 27

HUB SEAL

INSTALLATION TOOL

DISC HEAD UNIT

Figure 29

OUTER BEARING

INNER AXLE NUT