26

(0.0)

Depends on length

when loaded

Material

Pinch Roller

Margin

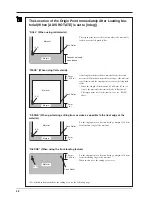

The Location of the Origin Point Immediately After Loading Ma-

terial (When [AXIS ROTATE] is set to [0deg])

“ROLL” (When using roll material)

The origin point is set at the location where the material is

loaded, near the left pinch roller.

(0.0)

25 mm

(1 in.)

30 mm

(1-3/16 in.)

Material

Pinch Roller

Margin

“PIECE” (When using flat material)

After length in the direction of material feed is detected,

movement 25 mm back from the front edge of the material

is performed, and the origin point is set near the left pinch

roller.

* When the length of the material is 1,600 mm (63 in.) or

longer, the material is determined to be roll material.

The origin point is set in the same way as for “ROLL”

above.

(0.0)

25 mm

(1 in.)

Material

Pinch Roller

Margin

“F-EDGE” (When performing cutting from as close as possible to the front edge of the

material)

Set the origin point at a location having a margin of 25 mm

from the front edge of the material.

30 mm

(1-3/16 in.)

Pinch Roller

Material

(0.0)

“R-EDGE” (When using the front-loading feature)

Set the origin point at a location having a margin of 30 mm

from the trailing edge of the material.

When in this state, the cutting area is zero.

* For detailed information about the cutting area, see the following page.

Summary of Contents for CX-300

Page 21: ...21 POWER ERROR LED goes out 4 Turn off the power ...

Page 63: ...63 MEMO ...

Page 64: ...R5 020403 ...