45.

pass through the fan, then the cooler cores, and finally

exit the compressor cabinet. See Section 6.1m.

Improper lubricant.

Use recommended lubricants only—see Section 4.0

Faulty temperature regulating

valve.

Repair or replace as necessary.

Faulty sensors.

Check and replace. See Description of Operation.

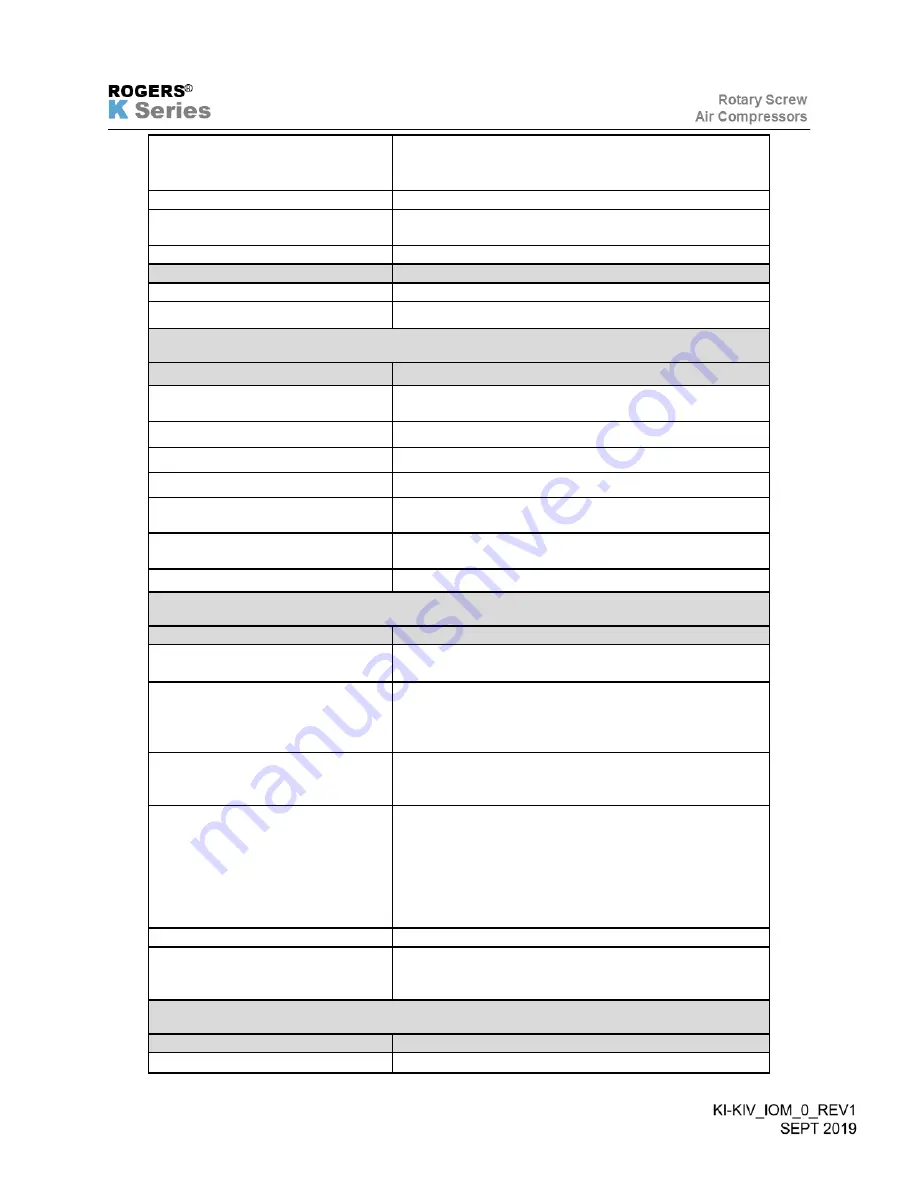

POSSIBLE CAUSE

CORRECTION

Air end failure.

Contact your Rogers factory representative.

Incorrect cooler installation.

Contact your Rogers factory representative.

7.10 COMPRESSOR DOES NOT LOAD

POSSIBLE CAUSE

CORRECTION

Improper pressure setting.

Correct pressure set points entered. See Description

of Operation.

Loose wiring connection.

Check and tighten wiring terminals.

Faulty air inlet valve assembly.

Check and repair air inlet valve.

Faulty unloading solenoid valve.

Repair or replace as necessary.

Faulty differential pilot valve or ice

in valve.

Orifice plugged, clean or replace as necessary.

Faulty control air regulator /

setting.

Replace, service, and/or set regulator.

Clogged control air filter.

Clean or replace filter element.

7.11 EXCESSIVE CYCLING BETWEEN LOAD AND UNLOAD

POSSIBLE CAUSE

CORRECTION

Insufficient system volume.

Provide additional volume by adding air receiver to

system. See Section 2.12.

Air pressure load and unload

settings too near the setting of the

differential pilot valve.

Set load pressure set point lower than differential pilot

valve setting. Separate load and unload settings in the

Compressor Control panel. See Description of

Operation.

Air pressure load and unload

settings are too close to each

other.

Reset load and unload settings. Typical settings are 10

psi apart

Downstream restriction in system

between compressor and air

receiver.

Check pressure drop from compressor discharge to

first storage receiver. Often filters or dryers will plug

creating excessive pressure drop which reduces the

control band of the compressor control and may cause

the compressor to short cycle. Check possible icing in

aftercooler and / or refrigerated air dryer. See section

7.16

Leaks in control lines.

Check and repair any leaks.

Contaminants in control system.

Drain lines, service filter, check differential pilot valve

orifice. Install heat tracing in cold environments (if due

to ice).

7.12 EXCESSIVE WATER IN PLANT AIR DISTRIBUTION SYSTEM

POSSIBLE CAUSE

CORRECTION

Clogged moisture separator/trap.

Clean or replace as required. See Section 2.9.

Summary of Contents for KI Series

Page 1: ...1 Model __________________ Serial __________________ Rotary Screw Air Compressors...

Page 8: ...7 INTENTIONALLY BLANK...

Page 9: ...8 CHAPTER 1 GENERAL INFORMATION...

Page 19: ...10 CHAPTER 2 INSTALLATION INSTRUCTIONS...

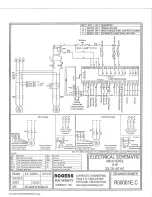

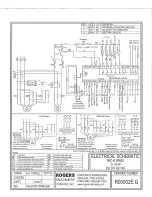

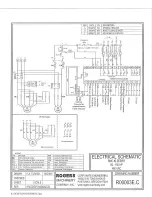

Page 26: ...17 CHAPTER 3 ELECTRICAL INFORMATION...

Page 30: ...21 CHAPTER 4 COMPRESSOR LUBRICANT...

Page 39: ...30 INTENTIONALLY BLANK...

Page 40: ...31 CHAPTER 5 AIR INLET FILTER INFORMATION...

Page 43: ...34 INTENTIONALLY BLANK...

Page 44: ...35 CHAPTER 6 COMPRESSOR OPERATIONS...

Page 49: ...40 INTENTIONALLY BLANK...

Page 50: ...41 CHAPTER 7 TROUBLESHOOTING...

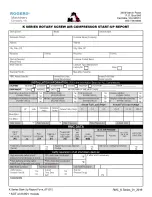

Page 57: ...48 CHAPTER 8 FORMS RECORDS AND ELECTRICAL SCHEMATICS...

Page 58: ...49...

Page 59: ...50...

Page 60: ...51...

Page 61: ...52...

Page 62: ...53...

Page 63: ...54...

Page 64: ...55...

Page 65: ...56 INTENTIONALLY BLANK...

Page 66: ...57...