23.

Check lubricant level in reservoir daily. Lubricant level must be checked with unit running at a consistent

pressure and loaded. The lubricant level should always be visible in the sight glass and never higher than

the run zone as indicated on the unit.

4.4

Lubricant System / Cooling Data

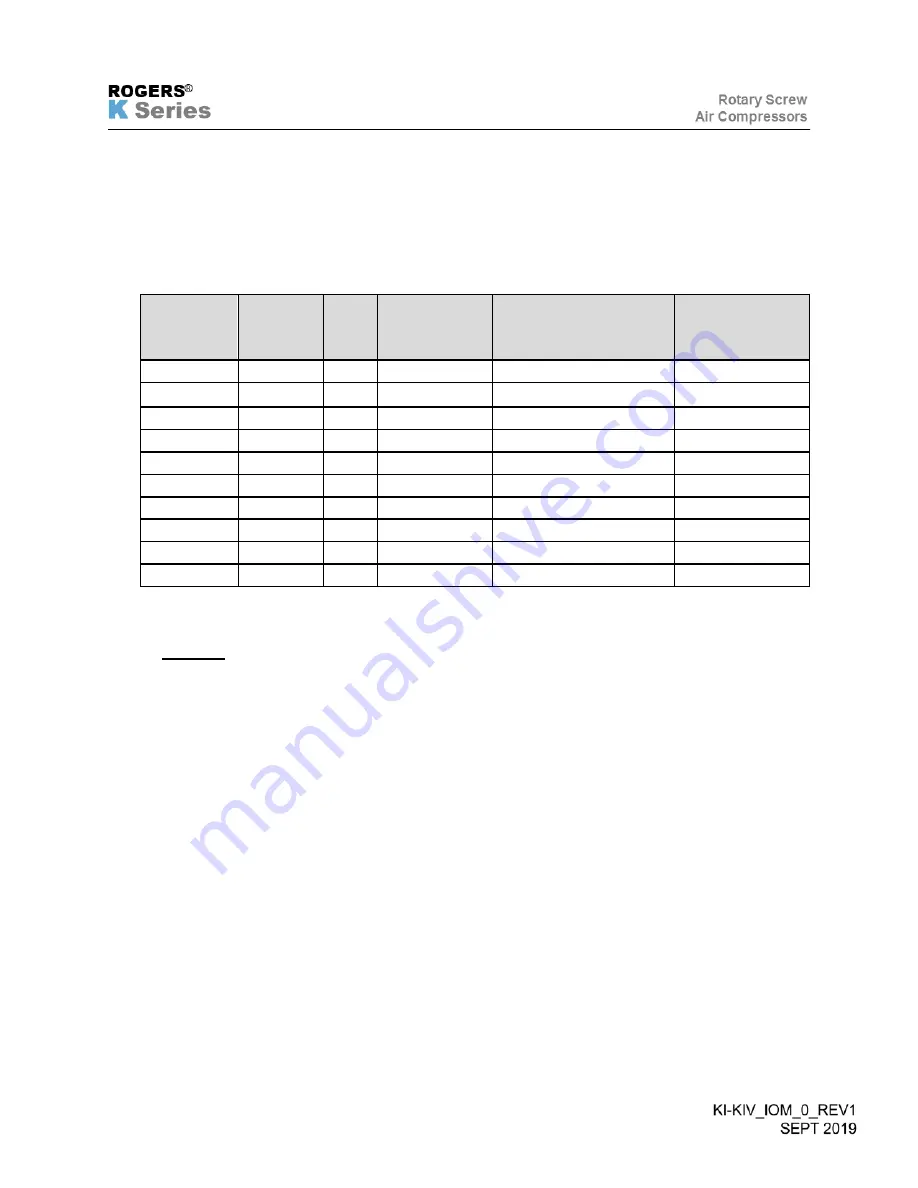

Table 1. Lubricant / Cooling Data.

4.5

Special Maintenance of Compressor Lubricant System

4.5.1 Deposits

Because the lubricant system operates under conditions of elevated temperature and pressure, solid or

semi-solid deposits may occur. However, proper installation, maintenance and filtration and lubricant

change intervals will greatly reduce the possibility of deposit formation.

Such deposits can interfere with operation of valves, filters and related cooling system equipment.

Minor deposits may be removed by flushing the system with an approved cleaning agent. Consult with

you Rogers factory representative for recommendations.

Completely drain lubricant while hot from every component that contains lubricant:

1. Replace lubricant filter and separator.

2. Fill machine with a factory-approved cleaning agent.

3. Operate the machine according to the cleaning agent manufacturer’s instructions, typically after

500 hours of operation.

4. Completely drain cleaning agent while hot from every component that contains lubricant.

A second flush may be required, as determined with laboratory testing.

1. Replace lubricant filter and separator.

2. Fill machine with new, clean lubricant.

MODELS

SYSTEM

CAPACITY

GAL (L)

FAN

HP

COOLING AIR

(CFM)

LUBRICANT COOLER

HEAT REJECTION

(BTU/MIN)

BLOWDOWN

HEAT REJECTION

(BTU/MIN)

KI/KIV-10

2 (7.5)

0.5

1,800

351

88

KI/KIV-15

3 (11.3)

0.5

1,800

537

134

KI/KIV-20

3 (11.3)

0.5

1,800

792

198

KI/KIV-25

4.25 (16)

1.0

3,600

976

244

KI/KIV-30

4.25 (16)

1.0

3,600

1,209

302

KI/KIV-40

7.5 (28)

1.0

3,600

1,463

373

KI/KIV-50

7.5 (28)

1.0

3,600

1,775

444

KI/KIV-60

8 (28.3)

1.0

3,600

1,880

470

KI/KIV-75

10 (37.8)

1.5

5,500

2,603

651

KI/KIV-100

12 (45.4)

3.0

8,900

3,257

814

Summary of Contents for KI Series

Page 1: ...1 Model __________________ Serial __________________ Rotary Screw Air Compressors...

Page 8: ...7 INTENTIONALLY BLANK...

Page 9: ...8 CHAPTER 1 GENERAL INFORMATION...

Page 19: ...10 CHAPTER 2 INSTALLATION INSTRUCTIONS...

Page 26: ...17 CHAPTER 3 ELECTRICAL INFORMATION...

Page 30: ...21 CHAPTER 4 COMPRESSOR LUBRICANT...

Page 39: ...30 INTENTIONALLY BLANK...

Page 40: ...31 CHAPTER 5 AIR INLET FILTER INFORMATION...

Page 43: ...34 INTENTIONALLY BLANK...

Page 44: ...35 CHAPTER 6 COMPRESSOR OPERATIONS...

Page 49: ...40 INTENTIONALLY BLANK...

Page 50: ...41 CHAPTER 7 TROUBLESHOOTING...

Page 57: ...48 CHAPTER 8 FORMS RECORDS AND ELECTRICAL SCHEMATICS...

Page 58: ...49...

Page 59: ...50...

Page 60: ...51...

Page 61: ...52...

Page 62: ...53...

Page 63: ...54...

Page 64: ...55...

Page 65: ...56 INTENTIONALLY BLANK...

Page 66: ...57...