7.1. Linear Axis

Caution

For every maintenance operation, please verify the axial backlash in the ball screw. If it is greater than 0.2 mm, the linear axis

must be replaced.

7.1.1. Components lubrication

Info

If needed, clean the components before the lubrication.

Info

Recommended lubricant : LUB-KC1.

Ball Screw and Bearing Guide Lubrication

Lubrication of the axis should be done every 2 years considering a typical use of 80h/ week. When lubricating, move the carriage all over

the axis stroke to distribute the lubricant uniformly.

Cover Strip and Guide Rail Lubrication

Lubrication have to be done if it is needed or when the component doesn't have its grease film anymore.

83

Summary of Contents for PALLETIZING SOLUTION

Page 12: ...Palletizing Solution Instruction Manual 12...

Page 72: ...6 1 2 AirPick Vacuum Gripper Fig 6 1 AirPick general dimensions 72...

Page 73: ...Palletizing Solution Instruction Manual 6 1 3 Extra Reach Bracket 73...

Page 74: ...6 1 4 Bracket for two 2 Suction Cups Fig 6 2 Two air nodes bracket s dimensions 74...

Page 80: ...80...

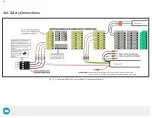

Page 95: ...1 2 2 Safety Connections Fig 12 2 Universal Robots Controller Safety Connections Schema 95...