PRINTER CONTROLLER SERVICE MODE

SM 5-3

G081/G092

Service

Tables

5.2 PRINTER CONTROLLER SERVICE MODE

NOTE:

In the Function/[Setting] column:

•

The related pop-up screen name and function name (if any) appear in

parenthesis following the function description.

•

Comments are in

italics

.

•

The setting range is enclosed in brackets, with the default setting written

in

bold

.

•

An asterisk (*) after the mode number means that this mode’s value is

stored in the NVRAM. If you do a RAM reset, all these SP modes will be

returned to their factory settings.

•

DFU

stands for

D

esign/

F

actory

U

se only. Values marked

DFU

should

not be changed.

•

FA

stands for

F

actory

A

djustment only. Values marked

FA

should not be

changed.

•

The Printer Controller is referred to as the Main Control Board.

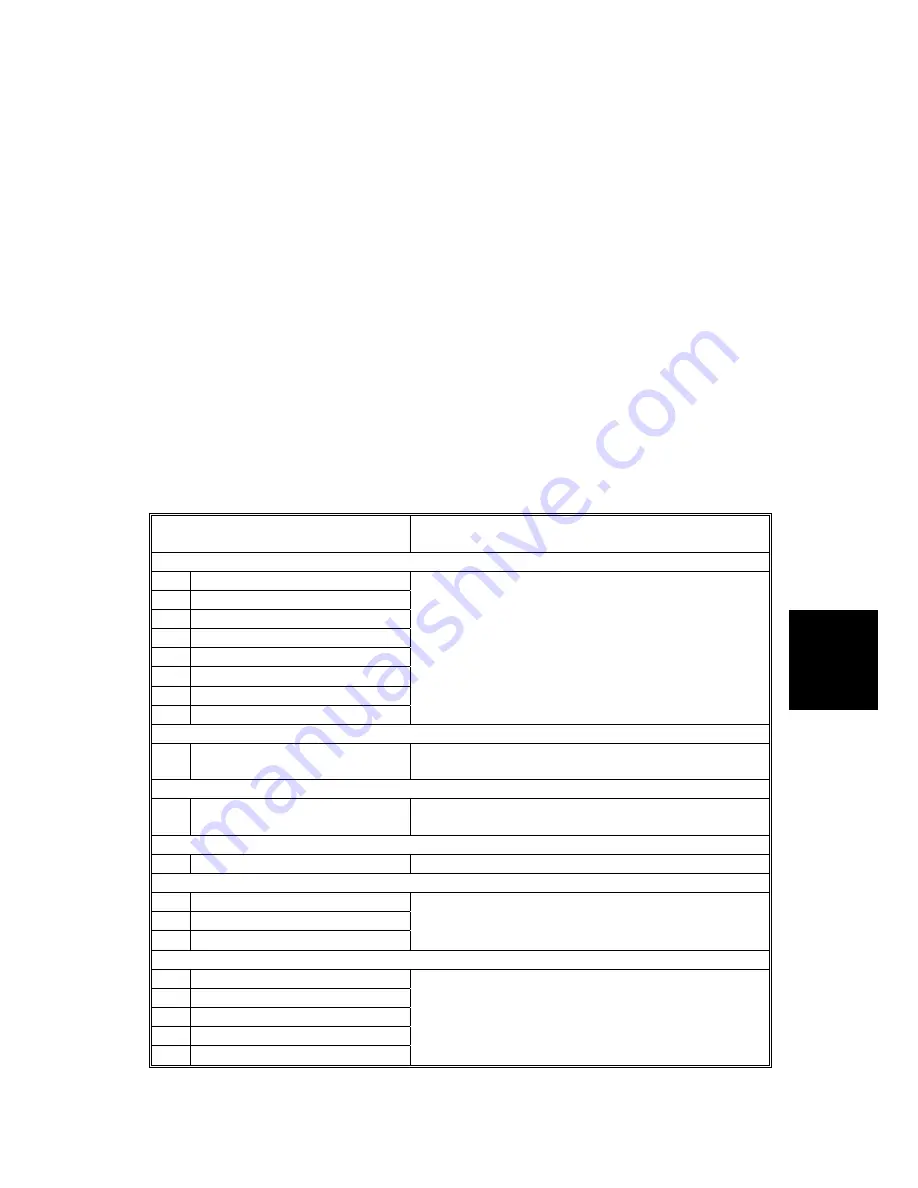

5.2.1 SERVICE MENU-CONTROLLER SERVICE MODES

(“1. SERVICE”)

Mode No.

(Class 1 and 2)

Function / [Setting]

[Bit Switch]

– SP1001

1

Bit Switch 1

2

Bit Switch 2

3

Bit Switch 3

4

Bit Switch 4

5

Bit Switch 5

6

Bit Switch 6

7

Bit Switch 7

8

Bit Switch 8

(See “Bit Switch Settings”.)

[Clear Setting]

– SP1003

1 Clear

Setting

Initializes the settings in the “System” menu of the

user tools.

[Print Summary]

– SP1004

1 Print

Summary

Prints the service summary sheet (a summary of all

the controller settings).

[DispVersion]

Display Version – SP1005

1

Disp Version

Displays the version of the controller firmware.

[ToneCtlSet]

Toner Control Setting – SP1101

1 Tone

(Factory)

2 Tone

(Prev.)

3 Tone

(Current)

Recalls the gamma settings. Select the factory,

previous, or current setting.

[ToneCtlSet]

Toner Control Setting – SP1102

1

*1200 x 1200 Photo

2

600 x 600 Text

3

1200 x 600 Text

4

600 x 600 Photo

5

1200 x 600 Photo

Selects the printing mode (resolution) for the printer

gamma adjustment. When selecting a print mode,

an asterisk (*) is displayed in the front of the mode.

⇒

Rev. 10/2003

Summary of Contents for G081

Page 1: ...G081 G092 SERVICE MANUAL 001481MIU RICOH GROUP COMPANIES...

Page 2: ......

Page 3: ...G081 G092 SERVICE MANUAL RICOH GROUP COMPANIES...

Page 4: ......

Page 5: ...G081 G092 SERVICE MANUAL 001481MIU...

Page 6: ......

Page 8: ......

Page 10: ......

Page 12: ......

Page 24: ......

Page 26: ......

Page 27: ...INSTALLATION...

Page 28: ......

Page 52: ......

Page 53: ...PREVENTIVE MAINTENANCE...

Page 54: ......

Page 57: ...REPLACEMENT AND ADJUSTMENT...

Page 58: ......

Page 103: ...TROUBLESHOOTING...

Page 104: ......

Page 123: ...SERVICE TABLES...

Page 124: ......

Page 161: ...DETAILED DESCRIPTIONS...

Page 162: ......

Page 246: ......

Page 247: ...SPECIFICATIONS...

Page 248: ......

Page 254: ......

Page 255: ...G342 PAPER FEED UNIT TYPE 3000...

Page 256: ......

Page 258: ......

Page 266: ......

Page 267: ...TECHNICAL SERVICE BULLETINS...