P

AGE

4-21

1117539, V

ER

. 07

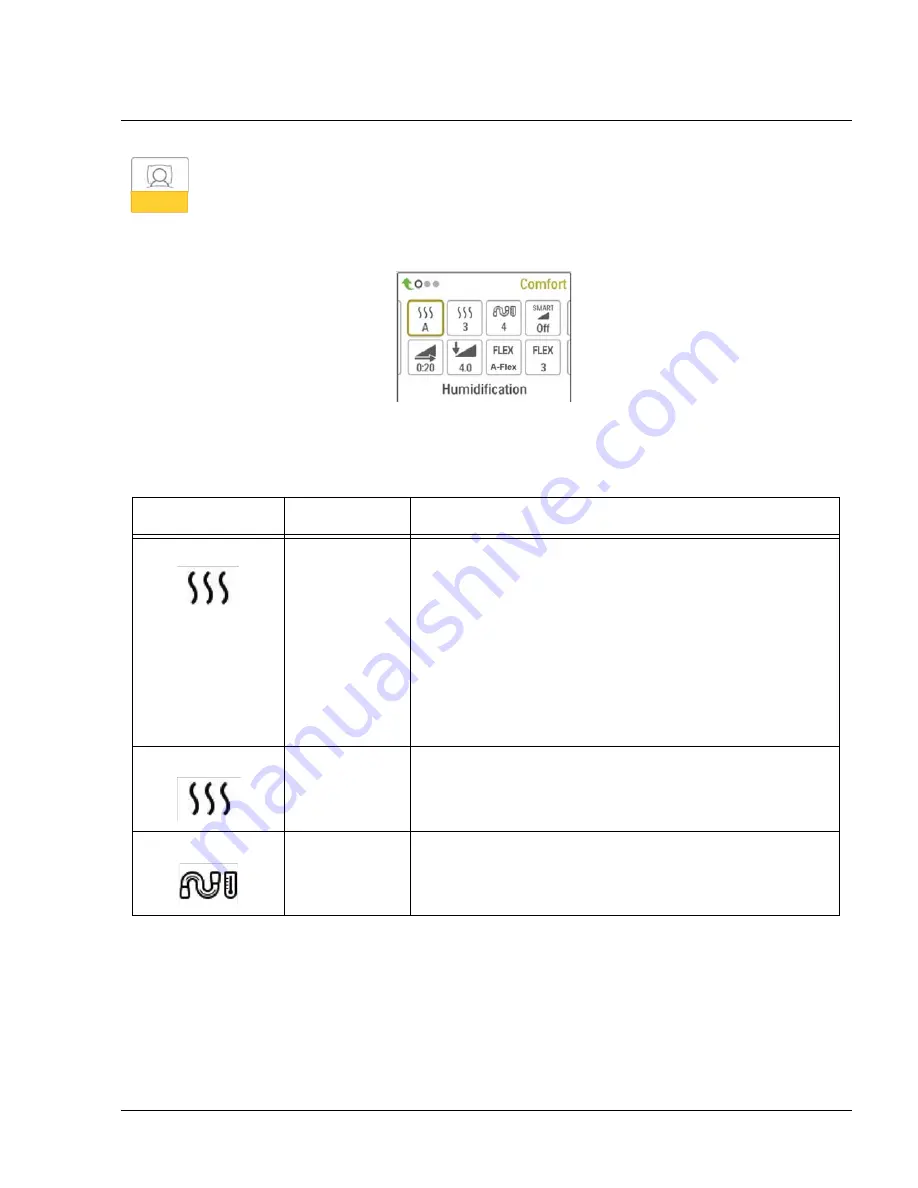

Comfort Settings:

Choosing this screen will take you to a sub-menu where you can adjust the humidification and pressure

comfort settings. These settings are described here.

F

IGURE

4-22: S

AMPLE

C

OMFORT

S

UB

-M

ENU

Note:

Not all settings shown here will display on the device. The display will vary based on therapy device

model and device settings.

I

CON

T

EXT

D

ESCRIPTION

Humidification

This setting allows you to select the Humidification Mode

being used. You can choose between Fixed or Adaptive (A)

Humidification. If a heated tube is attached to the device, then

the device will automatically switch to Heated Tube

Humidification Mode.

Fixed mode applies a constant heat on the humidifier heater

plate. Under certain conditions and settings, this mode can

allow condensation to occur in the tube.

Adaptive mode adapts the heater plate temperature to the

ambient conditions in the room, and is designed to not allow

condensation to occur in the tube.

Humidifier

This setting allows you to choose the desired humidity setting

for the humidifier: 0, 1, 2, 3, 4 or 5.

Tube

Temperature

This setting allows you to choose the desired temperature for

the heated tube: 0, 1, 2, 3, 4 or 5.

Summary of Contents for DreamStation

Page 1: ...DreamStation Service Technical Reference Manual ...

Page 5: ...1117539 VER 07 This page intentionally blank ...

Page 6: ...PAGE 1 1 1117539 VER 07 2016 Koninklijke Philips N V All rights reserved ...

Page 11: ...PAGE 1 6 1117539 VER 07 This page intentionally blank ...

Page 13: ...PAGE 2 2 1117539 VER 07 This page intentionally blank ...

Page 15: ...PAGE 3 2 1117539 VER 07 This page intentionally blank ...

Page 134: ...PAGE 8 8 1117539 VER 07 This page intentionally blank ...

Page 135: ...NO 1117539 VER 07 EMH 06 04 2016 ...