Section II - Description

10

Quincy Compressor-QSI

®

Electrical System

A diagram of the electrical system is shown in the parts

manual sent with the compressor. A wiring diagram

is also included in the control panel on all Quincy QSI

compressors.

NOTICE!

Due to continuing product improvements and

updates, it is suggested that the wiring diagram

included in the control panel be used when servic-

ing the electrical control.

Standard drive motors are open drip proof 1800 RPM

with a maximum ambient temperature rating of 104°F.

They are not suitable for salt laden, corrosive, dirty, wet

or explosive environments.

The QSI series compressors utilize 460V incoming power

through an across-the-line magnetic starter. A trans

-

former in the control panel reduces this voltage to 120

VAC for the various controls on the unit. These controls

include the selector switch, pressure switch, timer, high

air temperature safety switches, solenoid and the vari-

ous indicator lights. Other incoming line voltages are

available as options. The compressor is provided with a

NEMA 1 enclosure. Optional panels include NEMA 4.

Air-cooled models utilize a second magnetic starter for

protection of the fluid cooler fan motor. This starter is

connected to the compressor starter through an interlock

which insures the fan motor is operating with the com-

pressor motor. If the fan motor starter trips out for any

reason, the compressor unit will shut down.

DANGER!

High voltage could cause death or serious injury.

Disconnect all power supplies before opening the

electrical enclosure or servicing.

Safety Sensors

Two high air temperature

(HAT)

sensors are standard on

the QSI units. These sensors protect the unit by sensing

unusually high temperatures and shutting the unit down.

One is located in the discharge line from the compressor

to the air/ fluid reservoir. The second is located in the top

of the air/fluid reservoir. These sensors are set to trip at

approximately 225°F. The sensors are nonadjustable.

WARNING!

Never remove, bypass or tamper with the safety

HAT switch. Failure to provide this safety feature

could cause death or serious injury and property

damage. If the compressor is shutting down due

to high discharge temperature, contact a qualified

service technician immediately.

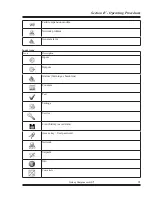

Summary of Contents for QSI Series

Page 2: ......

Page 7: ...Section I General Quincy Compressor QSI 5 MODEL IDENTIFICATION...

Page 62: ...Section IV Operating Procedures 60 Quincy Compressor QSI 1 Week Timer 2 Remaining Running Time...

Page 79: ...Section IV Operating Procedures Quincy Compressor QSI 77...