4300 ACT Wood Stove Series

Page 22

250-7061C December 10, 2004

R

OPACITY

This is the measure of how cleanly your stove is burning. Opacity is measured in percent; 100% opacity is when an object

is totally obscured by the smoke column from a chimney, and 0% opacity means that no smoke column can be seen. As you

become familiar with your stove, you should periodically check the opacity. This will allow you to know how to burn your stove

as nearly smoke-free as possible (goal of 0% opacity).

BURN RATES

•

STARTING FIRE:

Open (push in) both controls fully. After a wood load has been burning for 5 to 15 minutes (longer for very

large pieces) close the Start-Up Air Control by pulling it out (to the right of the stove).

•

HIGH:

Leave the Primary Air Control fully open (center of stove under the ashcatcher). It is important to do this when reloading

the stove. Failure to do this could result in excessive emissions (opacity).

After a wood load has been burning for 5 to 15 minutes on High to achieve the following burn rates

set the controls as listed below:

•

MEDIUM HIGH:

Close the Primary Air Control to 1-1/4” to 2-1/2” (32-64mm) open, Start-Up Air is closed.

•

MEDIUM LOW

: Close the Primary Air Control to 1” - 1-1/4” (25-32mm) open. Start-Up Air is closed.

•

LOW:

Gradually close down the Primary Air Control, making sure to maintain flames in the stove. (Start-Up Air is closed.) It is

very important to maintain flames in your stove during the first few hours of a low burn to avoid excessive air pollution.

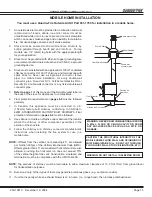

BLOWER OPERATING INSTRUCTIONS

(

See blower installation instructions on page 18)

If your Quadra-Fire wood stove is equipped with an optional blower, you should follow these guidelines:

1.

Initial (cold) start-up:

Leave blower off until your stove is hot and a good coalbed is established. The blower may be

turned on approximately 15 minutes after loading the stove with fuel.

2.

High burn setting:

The blower may be left on throughout the burn.

3.

Medium Low or Medium-High burn setting:

The blower should be left off until a good burn is established, then turned

on at a medium or high rate.

4.

Low burn setting

: The blower tends to cool off the stove. If you are using wet wood or a very low burn setting, leave

blower off until the burn is well established. Then, if you wish, turn the blower on at a lower rate. Too high a blower setting

with a low burn rate may adversely affect emissions.

5. The blower is equipped with a speed control. The highest blower speed is obtained by turning the speed control to“ON” and

then adjusting counterclockwise towards “OFF” as far as possible without turning the blower off. For a low blower speed,

turn the control knob clockwise as far as possible.

OPERATING INSTRUCTIONS (Cont’d)

CAUTION: DO NOT STORE WOOD CLOSER THAN THE REQUIRED CLEARANCES TO COMBUSTIBLE OF THE STOVE OR

WITHIN THE SPACE REQUIRED FOR LOADING AND ASH REMOVAL

.

WOOD SELECTION AND STORAGE

Burn only dry seasoned wood. Store wood under cover, out of the rain and snow. Dry and well-seasoned wood will not only

minimize the chance of creosote formation, but will give you the most efficient fire. Even dry wood contains at least 15% moisture

by weight, and should be burned hot enough to keep the chimney hot for as long as it takes to dry the wood out - about one hour.

It is a waste of energy to burn unseasoned wood of any kind.

Dead wood lying on the forest floor should be considered wet, and requires full seasoning time. Standing dead wood can

be considered to be about two-thirds seasoned. To tell if wood is dry enough to burn, check the ends of the logs. If there

are cracks radiating in all directions from the center, it is dry. If your wood sizzles in the fire, even though the surface is

dry, it may not be fully cured.

Splitting wood before it is stored reduces drying time. Wood should be stacked so that both ends of each piece are exposed to

air, since more drying occurs through the cut ends than the sides. This is true even with wood that has been split. Store wood

under cover, such as in a shed, or covered with a tarp, plastic, tar paper, sheets of scrap plywood, etc., as uncovered wood can

absorb water from rain or snow, delaying the seasoning process.