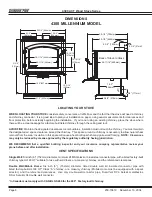

4300 ACT Wood Stove Series

Page 20

250-7061C December 10, 2004

R

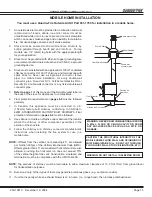

START-UP AIR

CONTROL

PRIMARY AIR

CONTROL

BURNING PROCESS

I

n recent years there has been an increasing concern about air

quality. Much of the blame for poor air quality has been placed

on the burning of wood for home heating. In order to improve

the situation, we at Quadra-Fire have developed cleaner-burning

wood stoves that surpass the requirements for emissions

established by our governing agencies. These wood stoves, like

any other appliances, must be properly operated in order to insure

that they perform the way they are designed to perform. Improper

operation can turn most any wood stove into a smoldering

environmental hazard.

KINDLING or 1st STAGE

It helps to know a little about the actual process of burning in

order to understand what goes on inside a stove. The first stage

of burning is called the kindling stage. In this stage, the wood is

heated to a temperature high enough to evaporate the moisture

which is present in all wood. The wood will reach the boiling

point of water (212°F) and will not get any hotter until the water

is evaporated. This process takes heat from the coals and

tends to cool the stove.

Fire requires three things to burn: fuel, air and heat. So, if heat

is robbed from the stove during the drying stage, the new load of

wood has reduced the chances for a good clean burn. For this

reason, it is always best to burn dry, seasoned firewood. When

the wood isn’t dry, you must open the air controls and burn the

stove at a high burn setting for a longer time to start it burning.

The heat generated from the fire should be warming your home

and establishing the flue draft, not evaporating the moisutre out of

wet, unserasoned wood, resulting in wasted heat.

The air control on the right side of the stove is called the Start -Up

Air Control; it is used during the kindling stage of burning. It must

be closed (pulled out) after the first

5 to 15 minutes.

2nd STAGE

The next stage of burning, the secondary stage, is the period when

the wood gives off flammable gases which burn above the fuel

with bright flames. During this stage of burning it is very important

that the flames be maintained and not allowed to go out. This will

ensure the cleanest possible fire. If you are adjusting your stove

for a low burn rate, you should close down the air to the point

where you can still maintain some flame. If the flames tend to

go out, the stove is set too low for your burning conditions. The

air control in the center of the stove beneath the ashcatcher, is

the one used to adjust the stove for burn rates. This is called the

Primary Air Control.

See Figure 20A.

FINAL STAGE

The final stage of burning is the charcoal stage. This occurs

when the flammable gases have been mostly burned and only

charcoal remains. This is a naturally clean portion of the burn.

The coals burn with hot blue flames.

It is very important to reload your stove while enough lively hot

coals remain in order to provide the amount of heat needed to

dry and rekindle the next load of wood. It is best to open the

air controls for a short while

before reloading

. This livens

up the

coalbed. Open door slowly so that ash or smoke

does not exit stove through opening. You should also break

up any large chunks and distribute the coals so that the new

wood is laid on hot coals.

Air quality is important to all of us, and if we choose to use

wood to heat our homes we should do so responsibly. To

do this we need to learn to burn our stoves in the cleanest

way possible. Doing this will allow us to continue using our

wood stoves for many years to come.

OPERATING INSTRUCTIONS

IMPORTANT - PLEASE READ BEFORE USING STOVE

START-UP AIR SYSTEM

The combustion air enters at the rear of the firebox through

the rear air tubes. This air supply is controlled by the

Start-up Air Control.

PRIMARY AIR SYSTEM

The primary air enters at the upper front of the firebox, near

the top of the glass door. This preheated air supplies the

necessary fresh oxygen to mix with the unburned gases, help-

ing to create secondary, tertiary and quaternary combustions.

This air is regulated by the Primary AirControl. For more

primary air push control in, for less air pull control out.

OPEN - PUSH IN Rod CLOSE - PULL OUT Rod

AIR CONTROLS

FIGURE 20A

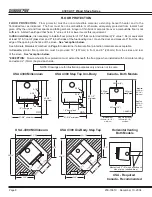

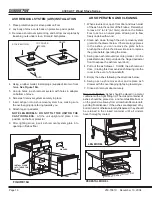

OPERATION OF TWO-STEP DOOR HANDLE

The 4300 is equipped with a two-step door handle. Turn the

door handle counter clockwise and open the door. The door

will open approximately one inch and stop. This allows for

the air flow to stablize and flow up the chimney and helps

prevent smoke spillage into the room. We recommend that

you pause at this stage to allow this to take place. Continue

to turn counter clockwise and now you can completely open

the door for refueling.

See Figure 25A on page 25

for instal-

lation instructions.