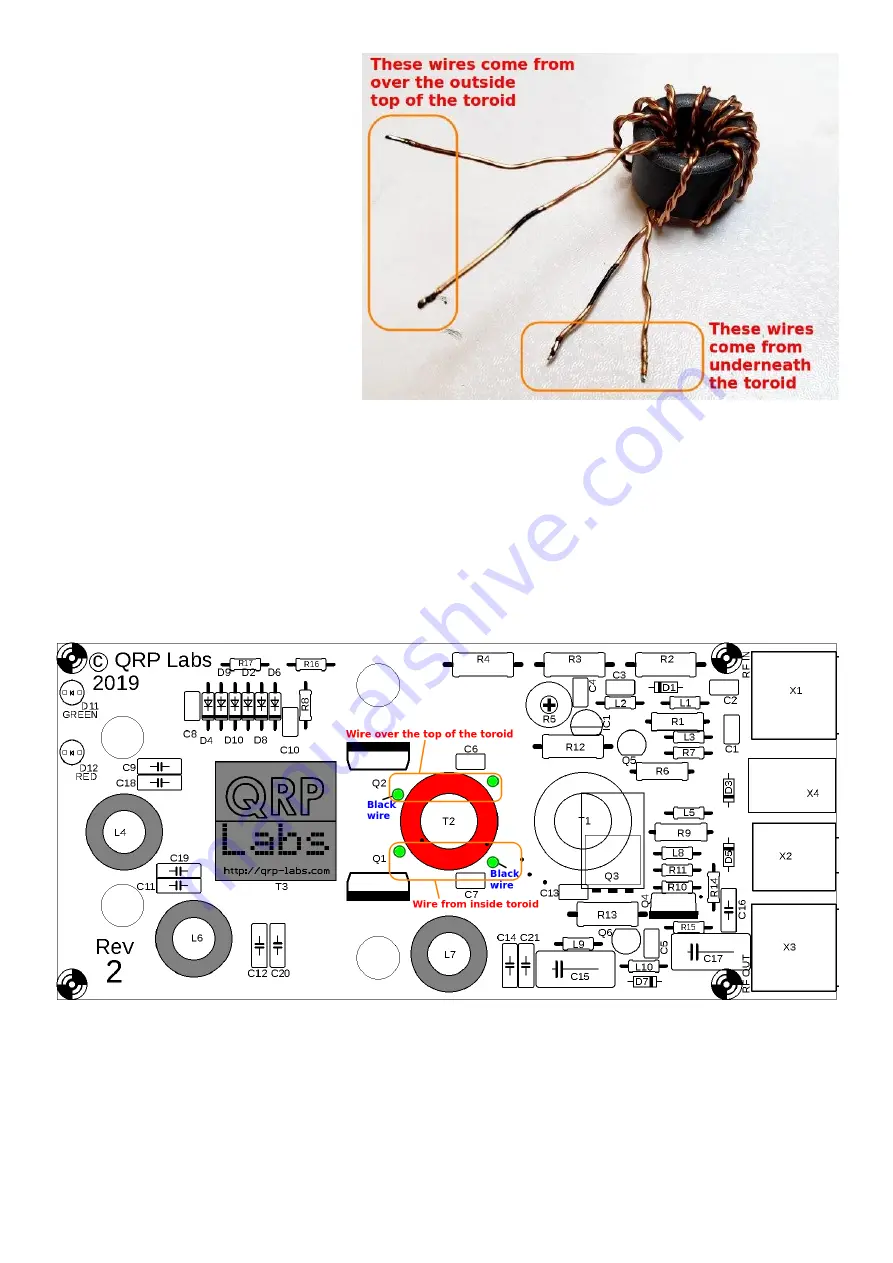

The diagram and explanation below

illustrates the correct wire placement.

It is CRITICALLY IMPORTANT to get

this right!

Now lay the toroid down flat on the

table as shown and identify the wires

which come from the center of the

core, over the top of the outside of the

core; and those which come out from

the underside of the toroid (see right).

All four wires go into holes that are on

the circumference of the outer circle of

the white silk-screen printing on the

PCB.

One black wire, that comes over the

outside of the top of toroid, must be inserted in the hole nearest the “Q2” text on the PCB (the top

left hole). The non-black wire that comes over the top of the outside of the toroid, which is twisted

together with this black wire, must be inserted in the hole nearest C6 (the top right hole).

One non-black wire coming from the underside of the toroid goes in the hole near the “Q1” text.

The corresponding black-marked wire goes in the hole near C7.

In this way, the lower pair of wires (Q1, C7) are from the twisted pair that comes from UNDER the

toroid; the top pair of wires (Q2, C6) are from the twisted pair that comes from the TOP side of the

toroid.

Pull the wires through the holes so that the toroid sits flat on the PCB, and is orientated accurately

with the white ink circle drawn on the PCB silkscreen. The toroid won’t sit perfectly flat of course,

because of the twisted bifilar windings. This is not a problem.

Squeeze the toroid gently to the PCB in the correct position, and cut the black-marked wire

nearest Q2, leaving a few spare mm. Now scrape some enamel from the last 5mm of this wire with

a knife or wire cutter; it does not have to be perfectly scraped but removing some enamel in this

way helps the remaining enamel to burn off easily. Tin it and solder it while it is in place in the hole

50W QCX PA kit assembly

1.00q

16