18

EN

SERIAL NUMBER

S / N:

____________________

(over 600 hours, print more of these pages at

www.portablewinch.com)

INSPECTION

INITIALE

#1

#2

#3

#4

#5

#6

Date

Hour meter reading(yes / no)

GEARBOX

Warning labels present and legible

Any leaks found

Gearbox oil level is OK

All screws and bolts are tight

Anchor hooks - no cracks, clasp is working

Shaft end-play less than 0.5 mm (0.020'')

Drum keyway is tight

Capstan shaft & seal area are clean

Rope entry pulley (brass pulley) rotating,

no flat section

Cracks in housing found

ROPE GRABBING SYSTEM/WINCH

CONTROLS

Main plate pivots freely

Pivot bolt is tight

No excessive wear on pivoting parts

Throttle control operational

CLUTCH

(PCH1000 / PCH2000 ONLY)

Clutch rotor is tight, no cracks or uneven

wear

Clutch drum is tight, turns freely, wall is >2

mm

MOTOR

(PCH1000 / PCH2000 ONLY)

Spark plug is clean with proper gap

Idle speed is adjusted

Valve clearance within specs

Fuel tank/filter are clean

Spark arrestor is clean

Oil is new and level is good

Air filter is clean

ROPES, HOOKS, LINKS

Rope is in good condition - whole length

Rope termination is not damaged

Hooks are in good condition

Links (shackles, carabiners, etc.) are good

Annex - Inspection of 100 hours

Part 1

Summary of Contents for PCH1000

Page 14: ...14 DE Annex PCH1000 ...

Page 15: ...15 DE Annex PCH2000 ...

Page 16: ...16 DE Annex PCT1800 50Hz P PCT1800 60Hz P ...

Page 17: ...17 DE Annex Diagramm PCT1800 50Hz P PCT1800 60Hz P ...

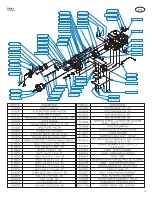

Page 34: ...14 EN Annex PCH1000 ...

Page 35: ...15 EN Annex PCH2000 ...

Page 36: ...16 EN Annex PCT1800 50Hz P PCT1800 60Hz P ...

Page 37: ...17 EN Annex diagram PCT1800 50Hz P PCT1800 60Hz P ...

Page 54: ...14 FR Annexe PCH1000 ...

Page 55: ...15 FR Annexe PCH2000 ...

Page 56: ...16 FR Annexe PCT1800 50Hz P PCT1800 60Hz P ...

Page 57: ...17 FR Annexe diagramme PCT1800 50Hz P PCT1800 60Hz P ...