EN

6

against the anchor point could prevent correct alignment. If that is the

case, release the tension on the rope and position the sling on the

anchor point so that the tension is equally distributed on both winch

anchor hooks.

DON'T DO THIS•!

WHEN YOU ANCHOR THE WINCH, MAKE SURE THAT YOU

DO NOT DO A COMPLETE WRAP AROUND THE ANCHOR POINT (FIGURE 2 BELOW).

THIS SET-UP WILL PREVENT PROPER ALIGNMENT OF THE WINCH WITH THE LOAD AND

WILL PUT UNEVEN TENSION ON THE WINCH ANCHOR HOOKS.

AVOID INSTALLING THE SLING ON SHARP EDGES THAT

MIGHT DAMAGE IT. WHETHER YOU ARE USING A POST, A

TREE OR A STUMP, ALWAYS INSTALL THE SLING NEAR THE ANCHOR'S BASE.

USING A STUMP AS AN ANCHOR POINT MEANS PAYING

SPECIAL ATTENTION IN ORDER TO PREVENT THE SLING

FROM SLIPPING OVER IT.

MAKE SURE THE ANCHOR POINT IS STRONG ENOUGH TO

RESIST THE PULL WITHOUT BREAKING OR BEING DAMAGED.

You can refer to our Website

www.portablewinch.com

to find out

about other anchoring accessories available

3.4

Oil Alert

MD

(PCH1000 and PCH2000 only)

The GHX-50 and GX160UT2-QX2 Honda engines are equipped with

an

Oil Alert

TM

system that automatically turns off the ignition when the

oil level goes below a safe level. The

Oil Alert

TM

system also turns off

the ignition when the winch is operating at an angle greater than 20

degrees (± 4 degrees). Make sure that your set-up keeps the winch

at a relatively horizontal level while winching and idling.

3.5

Installing the rope

1)

Figure 1: Open the rope

grabbing system (A) and

lock in place with spring

pin (B);

2)

Start the engine and let it

idle for 30 seconds to

warm-up

(PCH1000/2000);

3)

Figure 2: Run the rope

OVER

the rope keeper and the rope

entry pulley (A) and

UNDER

the drum. Then, wrap the

rope around the drum (B) 2-6

turns (according to the load

lifting chart of section 3.6.1.2);

4)

Figure 3: Insert the rope into

rope grabbing system device

by pulling the spring-loaded

cam lever upwards (A). This

will give enough room to

insert the rope.

5) Figure 4: Make sure the rope

goes over the stainless steel

knob (A). Then, push the

spring-loaded cam back

against the rope which will

automatically hold a load if the

rope end is let go (B).

6) Figure 5: As you pull the rope

(A), the throttle will engage and

load will move.

IMPORTANT

: It is necessary

to

pull

the

rope

HORIZONTALLY

to get

the

load started. To stop load

movement, stop pulling on

rope.

7) Stand about 1 m (3') from the winch and pull gently and

horizontally on the rope to get the slack until you feel the tension

rising on the rope;

8)

Look at your set-up to make sure that the winch anchor and the

rope entry pulley are aligned with the rope;

9)

Check that the rope does not rub against objects along the path;

10) Pull on the rope, the throttle will go up and the winching will start.

A

B

1

B

A

2

3

A

A

B

5

A

4

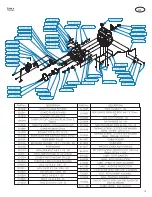

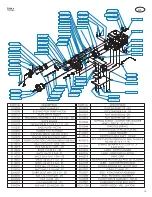

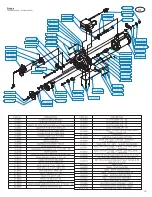

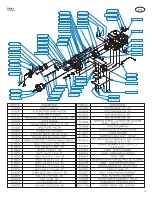

Summary of Contents for PCH1000

Page 14: ...14 DE Annex PCH1000 ...

Page 15: ...15 DE Annex PCH2000 ...

Page 16: ...16 DE Annex PCT1800 50Hz P PCT1800 60Hz P ...

Page 17: ...17 DE Annex Diagramm PCT1800 50Hz P PCT1800 60Hz P ...

Page 34: ...14 EN Annex PCH1000 ...

Page 35: ...15 EN Annex PCH2000 ...

Page 36: ...16 EN Annex PCT1800 50Hz P PCT1800 60Hz P ...

Page 37: ...17 EN Annex diagram PCT1800 50Hz P PCT1800 60Hz P ...

Page 54: ...14 FR Annexe PCH1000 ...

Page 55: ...15 FR Annexe PCH2000 ...

Page 56: ...16 FR Annexe PCT1800 50Hz P PCT1800 60Hz P ...

Page 57: ...17 FR Annexe diagramme PCT1800 50Hz P PCT1800 60Hz P ...