Automatic boiler for wood pellets

Instructions for installation and operation

MENU 8 – PROGRAMMES

It makes possible to store 6 completed programmes necessary for the automatic operation of the

boiler in memory of the control unit (1 – 5 heating, 6 heating service water) – see tab. 6.

MENU 9 – EL. HEATING

Applies to modification KPxx/E. See chapter 6.9.

MENU 10 – EL. IGNITION

See chapter 6.6.

MENU 11 – FLUE GAS VENTILATOR

In the construction.

MENU 12 – SETTING

It makes possible 2 levels of access – in Menu user and Menu manufacturer.

Menu user

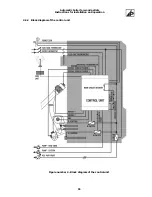

See figure number 6.

Menu manufacturer

The access in menu is protected by PIN code.

Further functions of the control unit

The control unit enables to control the automatic boiler for wood pellets with high level of comfort and

with a wide variety to adjust the optimum operating mode. See below some other functions of the control

unit:

1) Programmes (heating profiles - Menu 8) make it possible for the user to store 1 - 5

different adjustments of the boiler's operating modes in memory. This may be

advantageously used, for example, for different kinds of fuel or to adjust the required

power output. If a change is required, it is sufficient to read the required adjustment from

memory and to put the boiler in automatic operation.

2) Electric moderate heating (Menu 9). Applies to

KP xxE

, i.e. if the boiler is equipped with electric

heating coils (in course of production upon the customer's wish or additionally), the user may allow

or inhibit electric moderate heating. If the electric moderate heating is allowed, electric heating coils

will be turned on when the temperature of the heating water drops under 8

°

C; the electric moderate

heating will be turned off when the temperature of the heating water exceeds 12

°

C. The circulation

pump is in operation. Electric moderate heating can be used for moderate heating of buildings

which are not occupied permanently or to protect the heating system against freezing in time of

absence.

3) Ignition with electric resistance coil - see chapter 6.5.

4) Adjustment of some parameters of the boiler by user under simultaneous protection with

the PIN code seems to be advantageous, if the boiler is placed in rooms with possible

access of unauthorized persons. This prevents from undesirable interventions in some

functions of the boiler.

5) Control of cascade connection of 1 - 4 boilers. The function is adjusted by the service

engineer in course of putting into operation.

6) Protection of feeders with pulse sensors will stop the operation of the control unit, if the

expected number of pulses does not come to the input of the control unit. Feeders may be

blocked, for example, if improper fuel is used or if a foreign object gets in the transport

routes. Operator is notified of this situation with a script " BLOCKED FEEDER x " on the display unit.

It is protection of motors against damage and also a fire safety element (if only the feeder 2 gets

blocked, this might result in filling the whole transport route with fuel and the fuel might burn

through into the bin).

17

Summary of Contents for KP 10

Page 1: ......