Automatic boiler for wood pellets

Instructions for installation and operation

5.4 STORAGE OF FUEL

Wood pellets have to be in a dry place protected against atmospheric effects because humidity

damages them and aggravates their burning parameters. Excessive humidity completely destroys pellets.

They should be stored in a different room than the boiler or at least 1,500 mm from the boiler.

Operating stock of fuel may be stored in a special central bin which has to be manufactured from

non-combustible material. Bins supplied by the manufacturer meet operating and safety requirements. They

may be filled without any limits up to their total volume.

Large-volume bins have to meet corresponding fire and safety regulations. The supplier is obliged to work

out working regulations and instructions for operation and maintenance of large-volume bins.

5.5 BOILER ROOM VENTILATION

Permanent ventilation of the boiler within approximately 75 m

3

x hour

-1

of fresh air has to be

ensured, if a boiler of approximately 20 kW of power output is operated.

6 PUTTING THE PRODUCTS INTO OPERATION

6.1 CONNECTING TO THE SYSTEM

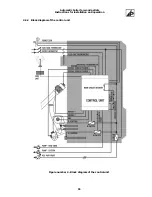

Connection to the system is performed in a usual manner - see the below given installation dimensions of

products. Recommended connection of the boiler to the heating system - see figures number 13, 14, 15.

Figure number 10 - Installation dimensions of boilers

23

Summary of Contents for KP 10

Page 1: ......