4.6

ELECTRONIC FUEL INJECTION

9924125 - 2013

RANGER

RZR / RZR S / RZR 4 Service Manual

© Copyright 2012 Polaris Sales Inc.

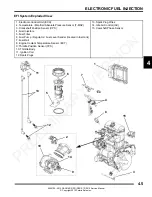

EFI System Component Locations

1.

Electronic Control Unit (ECU)

- Located behind the driver’s seat (RZR / RZR S) or

under the left rear passenger seat (RZR 4).

2.

Temperature and Manifold Absolute Pressure

Sensor (T-MAP)

- Located in the rubber intake boot between the

throttle body and the cylinder head.

3.

Crankshaft Position Sensor (CPS)

- Located in the magneto cover between the engine

and transmission, just in front of the rear gear case.

4.

Fuel Injectors / Fuel Rail

- Attached to the fuel rail located in the intake track of

the cylinder head.

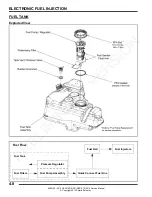

5.

Fuel Pump / Regulator / Fuel Gauge Sender

Assembly

- Located under the passenger seat (RZR / RZR S) or

under the right rear passenger seat (RZR 4).

ECU

RZR / RZR S

RZR 4

ECU

T-MAP

CPS

Fuel Rail

Fuel Injectors

Fuel Pump Assembly

RZR / RZR S

Shown

PRELIMINARY

VERSION

Summary of Contents for 2013 RANGER RZR

Page 417: ...2013 RANGER RZR 800...

Page 418: ...2013 RANGER RZR 800...

Page 419: ...2013 RANGER RZR 800 EPS...

Page 420: ...2013 RANGER RZR 800 EPS...

Page 421: ...2013 RANGER RZR S 800...

Page 422: ...2013 RANGER RZR S 800...

Page 423: ...2013 RANGER RZR S 800 INT L...

Page 424: ...2013 RANGER RZR S 800 INT L...

Page 425: ...2013 RANGER RZR 4 800...

Page 426: ...2013 RANGER RZR 4 800...

Page 427: ...2013 RANGER RZR 4 800 EPS...

Page 428: ...2013 RANGER RZR 4 800 EPS...