TROUBLESHOOTING PRESSURE GAUGE.

CHART 7902. OIL PRESSURE GAUGE

REMOVAL AND REPLACEMENT.

Refer to the General sectrion of Chapter 77 for Removal of Cluster Mounted Instruments.

OIL PRESSURE GAUGE CALIBRATION. (PA-44-180 S/N 44-95001 AND UP)

A calibration chart has been included for use in verifing that the suspected faulty gauge is within tolerance.

Actual recalibration of the gauge must be performed by the manufacturer or an approved instrument repair

facility.

1. With the instrument installed in the aircraft, the aircrafts’ power connected (14 VDC) and the ground

connected.

2. Remove the connection to the terminal marked SEND and connect a specified amount of resistance as

indicated on the chart, by use of a fixed resistor or a test unit capable of simulating the resistance indicated

on the chart (Power Resistor Decade Box).

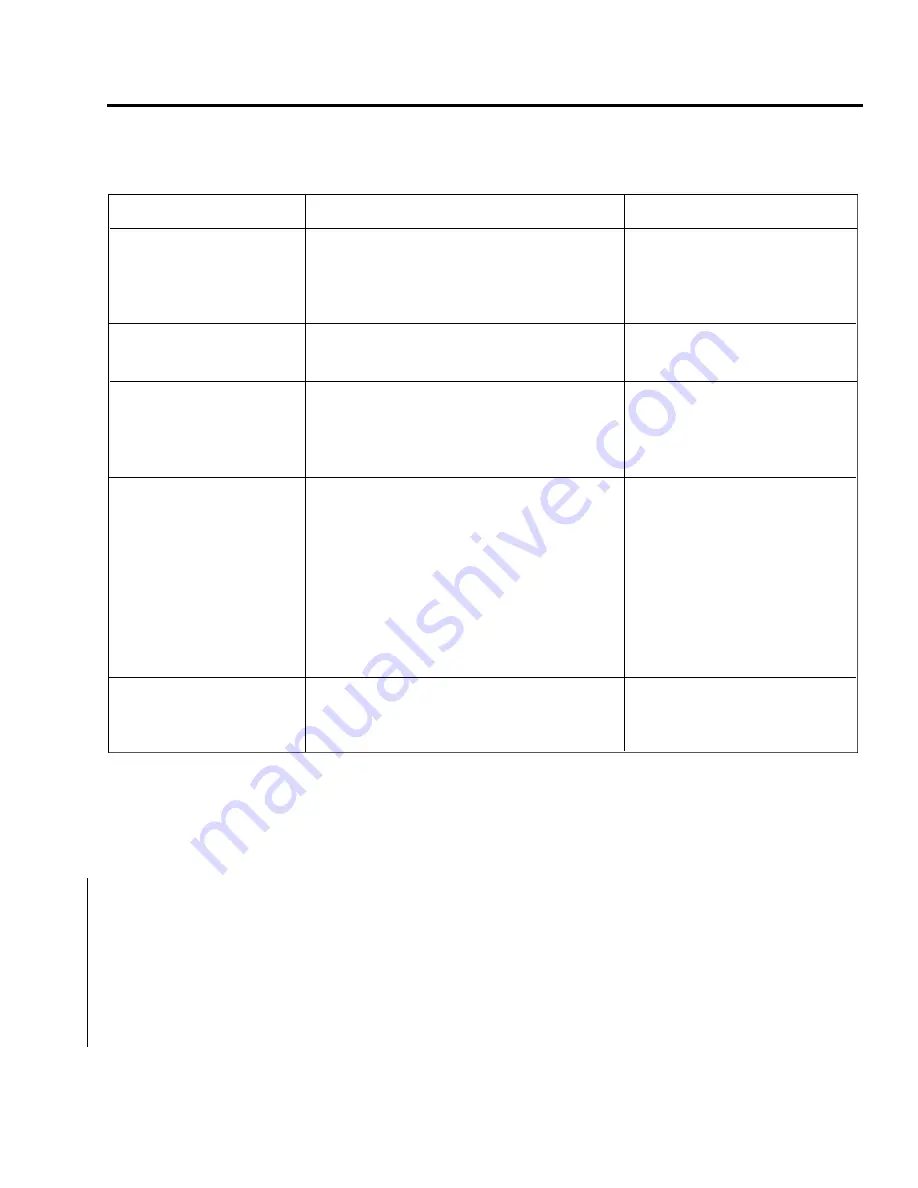

Trouble

Cause

Remedy

Excessive error at zero.

Pointer loose on shaft.

Repalce instrument.

Overpressure or seasoning

of burdon tube.

Excessive scale error.

Improper calibration

Replace instrument.

adjustment.

Excessive pointer

Air in line or rough engine

Disconnect line and fill

oscillation.

relief.

with light oil. Check for

leaks. If trouble persists,

clean and adjust relief valve.

Sluggish operation of

Engine relief valve open.

Clean and check.

pointer or pressure fails

to build up.

Line restriction to

Clean and check.

instrument.

Loss of oil in engine or

Shut down engine.

other engine failure.

NOTE

Gauge will take longer to indicate in cold weather.

PA - 4 4 - 1 8 0 / 1 8 0 T

AIRPLANE MAINTENANCE MANUAL

7 9 - 3 2 - 0 2

Page 79-03

Revised: May 15, 1989

3I5

PIPER AIRCRAFT

Summary of Contents for SEMINOLE PA-44-180

Page 38: ...CHAPTER DIMENSIONS AND AREAS 1B14...

Page 49: ...CHAPTER LIFTING AND SHORING 1C1...

Page 53: ...CHAPTER LEVELING AND WEIGHING 1C5...

Page 58: ...CHAPTER TOWING AND TAXIING 1C10...

Page 62: ...CHAPTER PARKING AND MOORING 1C14...

Page 65: ...CHAPTER REQUIRED PLACARDS 1C17...

Page 70: ...CHAPTER SERVICING 1C22...

Page 98: ...CHAPTER STANDARD PRACTICES AIRFRAME 1E2...

Page 108: ...CHAPTER ENVIRONMENTAL SYSTEM 1E12...

Page 189: ...CHAPTER AUTOFLIGHT 1H21...

Page 192: ...CHAPTER COMMUNICATIONS 1H24...

Page 202: ...CHAPTER ELECTRICAL POWER 1I10...

Page 228: ...CHAPTER EQUIPMENT FURNISHINGS 1J12...

Page 233: ...CHAPTER FIRE PROTECTION 1J17...

Page 238: ...CHAPTER FLIGHT CONTROLS 1J24...

Page 304: ...2A18 CHAPTER FUEL...

Page 325: ...2B17 CHAPTER HYDRAULIC POWER...

Page 357: ...2D1 CHAPTER ICE AND RAIN PROTECTION...

Page 414: ...CHAPTER LANDING GEAR 2F13...

Page 479: ...2I6 CHAPTER LIGHTS...

Page 488: ...2I16 CHAPTER NAVIGATION AND PITOT STATIC...

Page 503: ...2J7 CHAPTER OXYGEN...

Page 524: ...2K6 CHAPTER VACUUM...

Page 535: ...2K19 CHAPTER ELECTRICAL ELECTRONIC PANELS AND MULTIPURPOSE PARTS...

Page 546: ...INTENTIONALLY LEFT BLANK PA 44 180 180T AIRPLANE MAINTENANCE MANUAL 2L6 PIPER AIRCRAFT...

Page 547: ...2L7 CHAPTER STRUCTURES...

Page 582: ...CHAPTER DOORS 3A18...

Page 593: ...CHAPTER STABILIZERS 3B8...

Page 604: ...CHAPTER WINDOWS 3B22...

Page 611: ...CHAPTER WINGS 3C10...

Page 624: ...CHAPTER PROPELLER 3D1...

Page 643: ...CHAPTER POWER PLANT 3D21...

Page 667: ...CHAPTER ENGINE FUEL SYSTEM 3F1...

Page 681: ...CHAPTER IGNITION 3F16...

Page 712: ...CHAPTER ENGINE INDICATING 3H1...

Page 730: ...CHAPTER EXHAUST 3H19...

Page 734: ...CHAPTER OIL 3I1...

Page 743: ...CHAPTER STARTING 3I11...

Page 755: ...CHAPTER TURBINES 3J1...